LINEAR VIBRATION

TESTING AND ADJUSTING

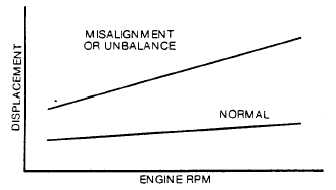

Misalignment or Unbalance

Most linear vibrations of generator sets are caused by

misalignment or unbalance of the rotating members.

This results in first order vibration which can be

corrected in the field.

The vibration motion is relatively constant over the

speed range but exceeds accepted limits. For generator

set applications this may be determined by operating

between 45 Hz to 65 Hz. Load does not change

vibration motion caused by unbalance.

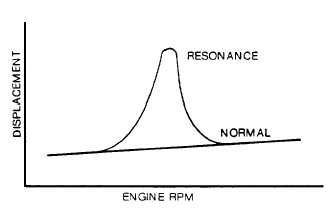

Figure 5

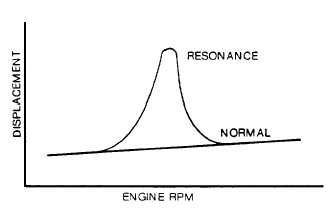

Resonance

Large vibration motion (amplitude) occurs within a

narrow speed range. This can occur on the generator

set and/or the attached equipment, such as piping, air

cleaners, etc. When vibrations "peak out" in a narrow

speed range, the vibrating component is in resonance.

Resonance occurs when the disturbing force in the

engine has the same frequency as the natural frequency

of the part which is vibrating. The force of the vibration

is, therefore, added to each cycle of the vibration part

causing magnification of the original vibration.

Figure 6

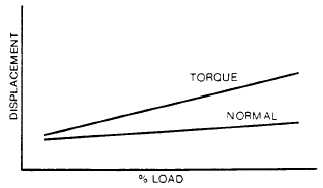

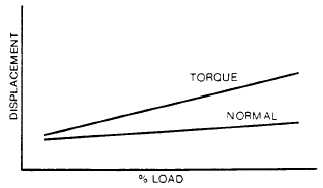

Torque Reaction

The vibration motion increases as load is applied. With

a two-bearing generator, it can be caused by insecure

mounting of the engine or generator to its base and/or by

a base not sufficiently rigid to withstand the associated

forces.

Figure 7

Torque reaction problems are not found with close-

coupled two-bearing or single-bearing generators. The

rigid joint between the flywheel housing and the

generator body is generally adequate to withstand

torque.

Assuming that a two-bearing generator is mounted on a

weak base, first order motion and orders related to the

number of cylinders firing with one crankshaft revolution

are due to torque reaction which, in turn, causes

misalignment. In this case, the first order motion would

be most prevalent. A few engines do not follow the

cylinder firing rule. These are the D346 and 0379 with

second order and the D349 and 0399 with fourth order,

in addition to the first order motion.

Certain specific causes of linear vibration can be further

identified:

Vibration Frequency

Correctable Causes

1/2 x Engine rpm

Misfiring of One or

(1/2 Order)

More Cylinders

1 x Engine rpm

Unbalance, Misalignment

(1st Order)

Out of Time Balance

Weights (3408), Crank-

case Overfill

2 x Engine rpm

Unbalance, Out of Time

(2nd Order)

Balance Weights,

Rotating Twice Engine

Speed (3304, D346, D379

1-1/2, 2-1/2, 3rd

Normal Cylinder Combus-

and Higher Orders

tion (Not Correctable)

105