TM 5-3825-226-24

out by the master cylinder piston causes the caliper

pistons to extend and apply the brakes. When the apply

force is released, a spring returns the master cylinder

piston and the brake fluid returns to the reservoir.

CAUTION: Always bleed air from the hydraulic brake

system when a line has been disconnected.

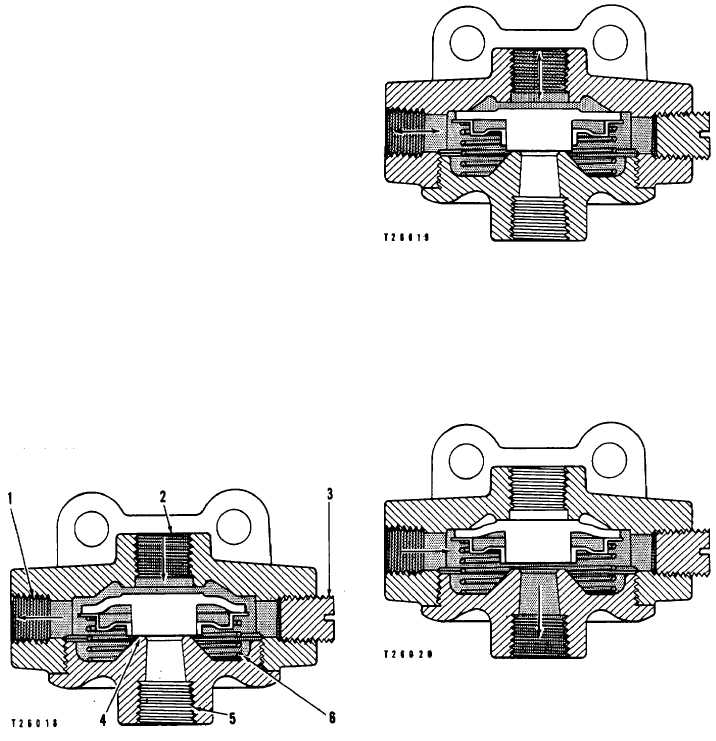

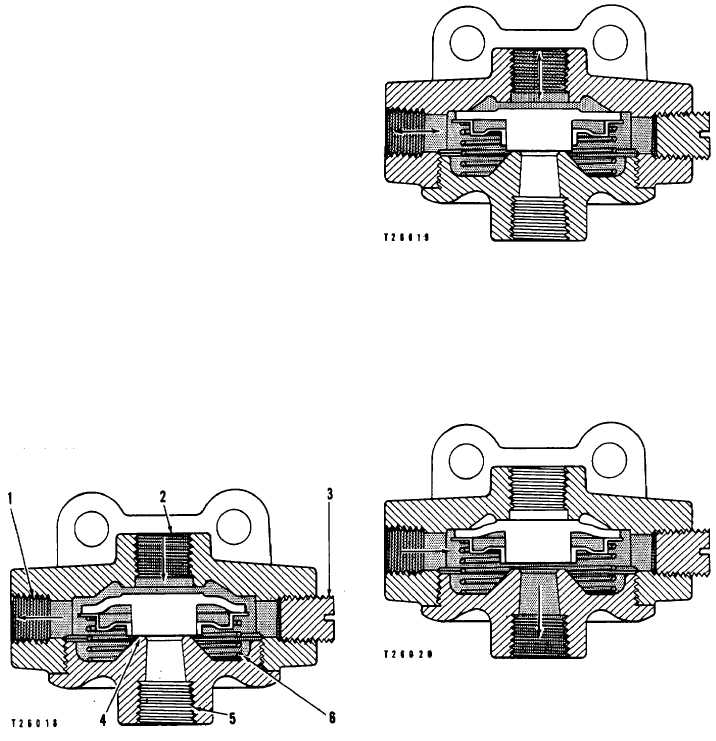

Quick Release Valve

The quick release valve releases the air from the

water distributor rotochamber. The quick release valve

has three positions. In the OPERATE position, pressure

air goes through the valve into the rotochamber. In the

HOLD position, pressure air is held in the rotochamber.

In the RELEASE position, air in the rotochamber is

released through exhaust passage (5).

When the brake pedal is pushed down, pressure air

goes into the inlet passage (2) of the quick release

valve. The diaphragm (4) moves down, closing the

exhaust passage (5). The outer edges of the diaphragm

are pushed down against the resistance of spring (6).

Pressure air goes through the outlet passage (I) to the

rotochamber.

QUICK RELEASE VALVE

(OPERATE POSITION)

1. Passage to rotochamber. 2. Inlet passage. 3. Plug.

4. Diaphragm. 5. Exhaust passage. 6. Spring.

When the pressure below the diaphragm is the

same as the pressure above the diaphragm, spring (6)

moves the edge of the diaphragm up against the valve

body. The center of the diaphragm still covers the

exhaust passage (5). This is the HOLD position.

QUICK RELEASE VALVE

(HOLD POSITION)

When the control valve for the service brakes is

released, air pressure on top of the diaphragm is

released. The air pressure in the rotochambers lifts the

diaphragm and opens exhaust passage (5). Air goes out

of the rotochambers through passage (1) to release the

brakes.

QUICK RELEASE VALVE

(EXHAUST POSITION)

Wheel Brakes

The friction pad (3) is pushed against disc (6) to

provide brakes for the machine. The discs turn with the

wheel hubs, and the calipers are connected solidly on

the axle flange. The brake assembly has two pistons

and a friction pad on each side of the disc. The pads

and backing are held in place by anchor pins. When

there is a brake application, oil, pushes the piston and

pads against the disc.

CAUTION: To prevent damage to pistons and seals, do

not push on brake pedal when brake pads are removed.

2-135