TM 10-4320-303-13

Table 2-7. Operator Preventive Maintenance Checks and Services for TWDS.

Location

Item

No.

Interval

Item to

Check/Service

Procedure

Not Fully

Mission Capable

if:

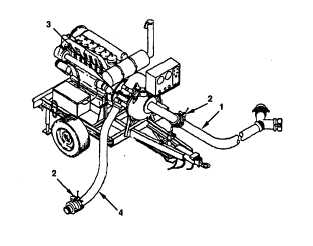

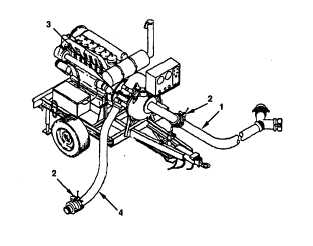

LEAD PUMPING

STATION

1

Before

Suction Hose

Assembly

Inspect for damage, leaks, and loose

connections. Tighten loose

connections. If hose is damaged or

Class III leaks are present, notify

supervisor.

Hose is damaged or collapsed.

Class III leak. Connection is

loose.

2

Before

6 Inch Butterfly

Valve

Ensure butterfly valves on hose

assemblies are in open position. If

valve will not open, notify supervisor.

Ensure butterfly valve on bypass hose

assembly is closed when not in use. If

valve will not close, notify supervisor.

Valve on suction and discharge

hoses will not fully open. Valve

on bypass hose assembly is

open.

3

Before

Check Valve

Ensure check valve is

Check valve is

installed properly. Arrow on

not installed

body casing must point in

properly.

direction of water flow. If

Connection is

valve is not installed

loose. Class

correctly notify supervisor.

III leak.

Inspect for leakage and loose

connections. Tighten loose

connections. If Class III

leak is present, notify

supervisor.

4

Before

Discharge Hose

Inspect for damage, leaks,

Hose is damaged

Assembly

and loose connections.

or collapsed.

Tighten loose connections.

Class III leak.

If hose is damaged or Class

Connection is

III leak is present, notify

loose.

supervisor.

2-15