TM 10-5430-243-12&P

0040 00

0040 00-3/4 blank

Table 2. Locknut Breakaway Torque Values.

NOTE

To determine breakaway torque, thread locknut onto screw or bolt until at least two

threads stick out. Locknut shall not make contact with a mating part. Stop the

locknut. Torque necessary to begin turning locknut again is the breakaway torque.

Do not reuse locknuts that do not meet minimum breakaway torque.

Thread

Minimum Breakaway Torque

Size

lb-in.

(N m)

10-32

2.0

(0.23)

1/4-28

3.5

(0.40)

5/16-24

6.5

(0.73)

3/8-24

9.5

(1.07)

7/16-20

14.0

(1.58)

1/2-20

18.0

(2.03)

9/16-18

24.0

(2.71)

5/8-18

32.0

(3.62)

3/4-16

50.0

(5.65)

7/8-14

70.0

(7.91)

1-12

90.0

(10.17)

1-1/8-12

117.0

(13.22)

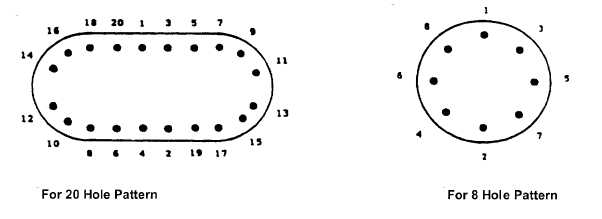

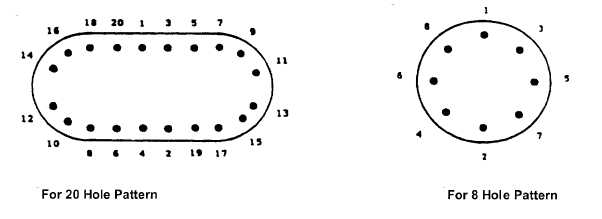

Torque Sequence

Torque value examples are established in the sequence shown and are itemized as follows:

Hand tighten bolts first. Next, using a torque wrench, tighten 3/8 bolts to a maximum of 15 foot pounds

(20.34 N m) for Reliance Models and a maximum of 16 foot pounds (21.70 N m) for GTA Container

Models. Second, tighten ¼ inch bolts to 30 inch pounds (3.39 N m). Last, tighten the ¼ bolts to a

maximum of 87 inch pounds (9.83 N m) or to the value specified in the applicable work package.

END OF WORK PACKAGE