TM 5-3820-256-10

(8)

Operate the hoist drum brake control (5, figure 2-4) slightly to release brake and allow slack in the cable and

lower the kelly in the mast. Then reset the brake. Repeat this procedure to slack the cable on the auxiliary and

third drums, using brake controls (4 and 6, figure 2-4).

CAUTION

If mast does not raise properly or mast binds, stop operation. Lower

mast and determine problem before proceeding. Otherwise, damage

may result.

(9)

Operate the mast control (1, figure 2-1) and raise the mast approximately two-thirds of the fully-raised position.

Release the control to stop movement. Then repeat Step 8.

(10) Operate the mast control (1, figure 2-1) and raise the mast to the fully-raised position and release the control.

Close both mast locks.

(11) Recheck the level of the rig.

g.

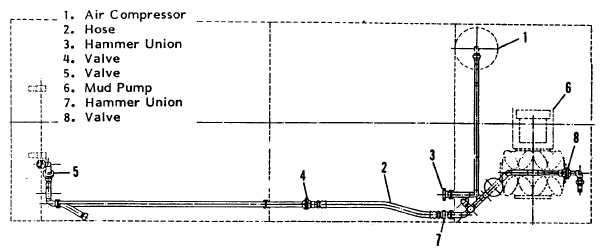

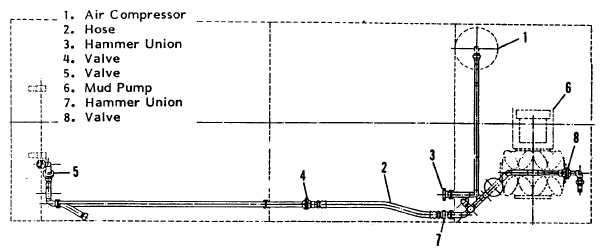

Connect discharge piping.

(1)

Be sure there is no pressure on the discharge line between the air compressor/ mud pump and the standpipe at

the mast. If there is, release the pressure with the blowdown valve (3, figure 2-5). Close the valve after

pressure is released.

NOTE

If the discharge piping is routed to the desired unit (air compressor or

mud pump) disregard the next step.

(2)

Use a hammer to break the hammer union connection. Unscrew the union; then connect the routing hose (2,

figure 2-28) to either the air compressor hammer union (3) or mud pump hammer union (7). Use a hammer to

tighten the union. Open discharge valves (4 and 5) by positioning the handles to run parallel to the piping. If

using the mud pump, be sure valve (8) is closed (handle perpendicular to piping).

Figure 2-28. Connecting Discharge Piping

2-50