4-6.4.2 Inspection and Repair.

a.

General. Discard all seals and thoroughly clean all parts: check that all machined faces and threads are free

from burrs, scores and other damage. Replace any damaged bolts, washers and circlips, etc.

b.

Bearings.

(1)

Examine each bearing for wear and damage, particularly on the faces, bearing bores and across the seal

bridge. The bearings' outer radii should be free from damage by contamination and aeration.

(2)

Ensure that the lubricating scrolls in the bearing bore are free from foreign matter and excessive oil

lacquer.

(3)

Check that the bearings are a sliding fit in the body bore.

(4)

If the bearings are not badly damaged they may be salvaged in the following way:

(a)

Place a sheet of O grade emery paper lubricated with paraffin on a truly flat surface, then polish the

bearing face using a light rotary motion.

(b)

Outer radii may be lightly polished to obtain free movement in the body. Maintain sharp corner on

outer face adjacent to gears.

c.

Body.

(1)

Inspect the pump body for external damage and cracks, etc. Examine the body bore for damage and

excessive wear. It is normal for the gears to have cut a light track in the body bore on the inlet side. If the

body is in good condition, with no excessive scoring or other damage of the gear track and the depth of the

track does not exceed 0.10mm (0.004"), the body is re-usable.

(2)

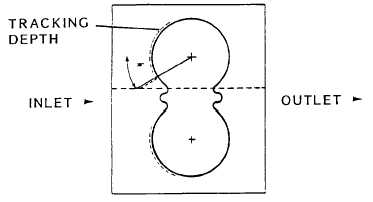

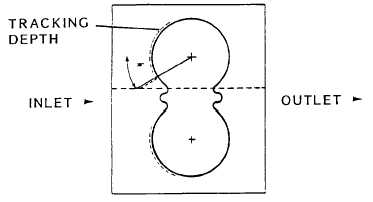

Using a Vernier height gauge and dial test indicator, measure the body bore track depth (Figure 4-17).

Figure 4-17. Body Bore Measurement

4-69