TM 5-3820-236-24-4

BATTERY

STORAGE INSTRUCTIONS

Always store batteries in an upright position. Never allow

batteries to be laid on their sides as electrolyte may

escape through the vent holes.

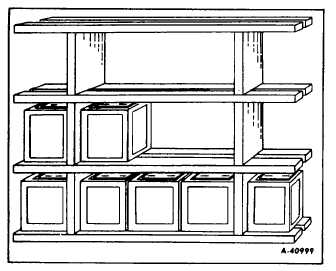

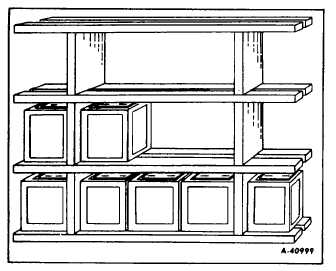

Never stack batteries on top of one another. Simple

battery storage racks can be made from loose, flat boards

supported by the batteries themselves, as shown in

Figure 15.

Figure 15 Battery Storage Rack

Batteries will slowly discharge while standing and will

discharge much faster when warm than when cold. On

wet type

conventional

batteries,

self-discharge

can

amount to about an average of .001 specific gravity per

day over a 30 day period. To minimize self-discharge,

store batteries In as cool a place as possible, away from

heat ducts in winter and shielded from direct sunlight in

summer.

Ideal storage conditions would be in a clean dry area

where temperature would be stable and as cool as

possible between 0OC (320F) and 26°C (80°F). Storage

in ambient temperatures above 260C (800F) is not

recommended as this increases the rate of self-discharge.

Temperatures below 0OC (32°F) should be avoided to

prevent freezing should a battery become discharged.

Wet batteries in storage should be checked for state of

charge every 30 days and charged whenever they fall to

1.225 specific gravity. A charge rate of one ampere for

each positive plate In one cell should be used to recharge

the battery.

NOTE - Batteries of vehicles standing In storage

should

be

considered

as

batteries

In

storage.

Vehicles In Inventory should be maintained regularly

to keep their batteries clean and dry, properly filled

with water and, most Important, fully charged.

Because of their chemical composition, maintenance free

batteries self-discharge at a slower rate than conventional

batteries. When stored as recommended, a shelf life of

up to twelve months or more, depending upon storage

temperatures, is possible before charging is required.

Maintain proper battery stock rotation. The first batteries

placed in storage should be the first ones taken out. (Be

sure to check date codes on the batteries and the

cartons.)

If a battery has been in storage for some time, it should

be charged before being installed in a vehicle.

ACTIVATING DRY CHARGED BATTERIES

Dry

charged

batteries

provided

for

replacement

installation must be "activated" before they can be used.

Following the instructions outlined below will assure

proper

activation

regardless

of

temperature

and

conditions of storage.

NOTE - Always refer to and follow manufacturer’s

activation Instructions furnished with battery.

1.

Fill each cell of the battery to the top of the

separators with the correct battery-grade electrolyte

as specified by the manufacturer's instructions.

Using higher or lower specific gravity electrolyte than

recommended can impair battery performance.

Originally filling each cell to the top of the separators

permits expansion of the electrolyte as battery is

boost charged.

2.

Gently rock battery. This will help to force out

trapped air and to saturate the plates with electrolyte.

3.

Boost charge 12-volt batteries at 15 amps (6-volt and

12-volt heavy duty batteries at 30 amps) until the

specific gravity of the electrolyte is 1.250 or higher

and electrolyte temperature is at least 15.5°C (60°F).

BOTH CONDITIONS MUST BE MET. If electrolyte

bubbles violently while charging, reduce charging rate

until excessive bubbling action subsides, then

continue charging until 1.250 specific gravity and

15.50C (600F) are reached.

If the ambient temperature is 0°C (320F) or less, it is

imperative that the above instructions be followed.

4.

Check volume of electrolyte in all cells and adjust to

prescribed level with additional electrolyte as

required.

5.

Install battery in vehicle as instructed under

REMOVAL AND INSTALLATION. Be sure of proper

polarity.

Dry charged batteries may be placed in service

immediately after activation. However, to insure good

performance these additional steps are recommended .

CTS-4111B - Page 16