SERVICE MANUAL

CYLINDER HEAD & VALVES

Section 3

2.

Turn the engine forward to approximately BDC

(Bottom Dead Center).

3.

Place a 0.10 mm (.004 in.) feeler gauge between

the valve lever and valve stem of the No. 1

intake valve and slowly rotate the engine forward

until the feeler gauge becomes tight. This is now

the point at which the No. 1 intake valve starts

to open before top dead center. The following

degree readings should be read on either

vibration damper or flywheel depending on the

application.

Engines

Readings

D-312 Below Eng. S/N 2505

30 ± 3

D-312 Eng. S/N 2505 and

23 ±

3

Above

D-360 and DT-360

30 ± 3

All 400 Series Engines

24° ± 3

NOTE: One (1) tooth "out of time" on gear train

equals approximately 11 degrees movement of

vibration damper.

NOTE: If the timing on the No. 1 valve is within

specifications, the other valves barring extreme

camshaft lobe wear or poor adjustment will also be

in time.

4.

Readjust the No. 1 intake valve to its proper

lash as described in this section.

5.

If timing is found to be incorrect, removal of the

engine's front cover is required to inspect punch

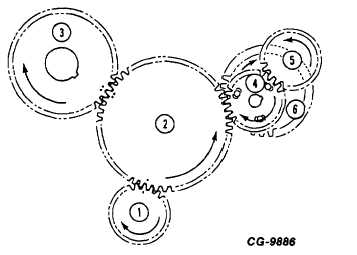

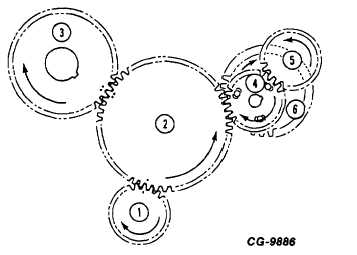

mark and gear tooth position. Figure 39 depicts

a properly timed assembly and number of teeth

between marks.

.

Crankshaft Gear

2.

Idler Gear

3.

Camshaft Gear

UTDS*

4.

Injection Pump Drive Gear

Model 100

5.

Tachometer Drive Gear

Fuel Injection

(if equipped)

Robert Bosch

6.

Injection Pump

Fuel Injection

Drive Gear

Model MW

Figure 39. - Properly Timed Gear

Train Assembly

22.5

TEETH BETWEEN PUNCH

MARK 1 AND PUNCH MARK 2.

CG-9885

*United Technologies Diesel Systems (formerly AMBAC)

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 32