SERVICE MANUAL

CLEANING, INSPECTION AND REPAIR

Remove all dirt, old lubricant, and liquid gasket

material from components of the rear axle. Immerse in

cleaning solvent and use a stiff brush if necessary.

Bearings should be cleaned separately in clean solvent

and special efforts taken to protect their finely machined

surfaces. If compressed air is used for drying, do not

spin bearings while drying.

Examine all bearings for roughness, damage or

wear by rotating each bearing slowly in the hand. If in

doubt as to bearing condition, replace. Ring gear, drive

pinion, differential pinions and any other gears should be

checked for damaged teeth, worn spots, or distortion.

Inspect diff case assembly for cracks, damage or

distortion. Make sure splined ends of axle shafts are

neither twisted nor cracked. Shim packs should be

uniform thickness. Discard thrust washers and obtain

new even when only slight wear is indicated.

ADJUSTMENTS

The principal adjustments made on the diff

carrier assembly are devised for establishing the proper

gear tooth contact and thereby obtaining a long wearing,

quiet running rear axle. Fundamentally, there are five

adjustments to be covered and these are accomplished

as the diff carrier assembly is assembled. To emphasize

their importance, these five steps or adjustments are

listed here as well as in the actual assembly procedure.

These adjustments are:

1.

Preload the pinion bearings.

2.

Set pinion nominal dimension.

3.

Set gear lash.

4.

Preload the diff bearings.

5.

Check gear tooth contact.

REASSEMBLY

When reassembling the rear axles, see also the

exploded views (Figs. 23 and 24) for correct installation

of parts.

FORWARD REAR AND REAR AXLES

Assemble Pinion and Cage

1.

Place rear pinion bearings on pinion shaft and

press into place against pinion.

2.

Place pilot bearing on stud end of pinion shaft

and press firmly against shoulder of

pinion. Stake face of pinion shaft in six (6)

evenly spaced places to secure pilot bearing in

place (Fig. 25)

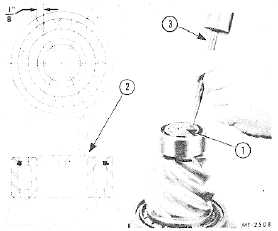

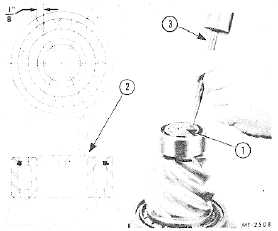

Fig. 25. Staking Pinion Pilot Bearing

1

Ground Face of Pinion

2

Metal Displaced to Secure Bearing

3

Blunt Point Punch

3.

Pre-lubricate the bearings with rear axle gear

lubricant.

4.

Place bearing spacer on pinion shaft and press

against rear pinion bearing.

IMPORTANT

The bearing spacer is furnished in various

thicknesses in graduations of .025 mm

(.001”) to permit changing of spacer

thickness to obtain correct pinion bearing

preload.

5.

Insert pinion (with rear pinion bearing and

spacer) into pinion cage.

6.

Mount pinion and cage in arbor press. Place

pre-lubricated front pinion bearing on pinion.

7.

Press bearing into place firmly against

bearing preload spacer.

8.

Revolve pinion cage around pinion several

times to seat bearings correctly.

9.

Remove pinion and cage from press.

CTS-4044

PRINTED IN UNITED STATES OF AMERICA

Page 15