TM 5-3825-226-24

ADJUSTMENT AND CLEANING OF 9N3979 FUEL

INJECTION NOZZLES

NOTE: Do not clean or adjust a nozzle with a valve

opening pressure (VOP) less than 1500 psi (10300 k

Pa).

Valve Opening Pressure (VOP) Adjustment

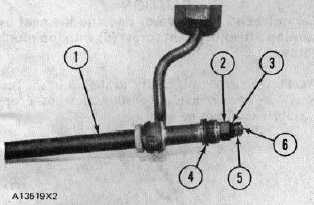

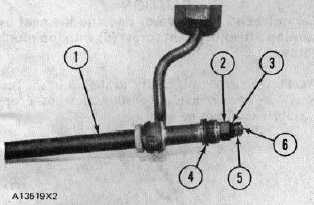

FUEL INJECTION NOZZLE

1. Fuel injection nozzle. 2. Locknut (for pressure

adjustment screw). 3. Pressure adjustment screw.

4. 1H1023 O-ring Seal for cap. 5. Locknut (for lift

adjustment screw). 6. Lift adjustment screw.

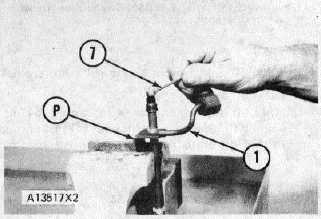

1. Remove fuel injection nozzle (1) from the 5P4150

Nozzle Tester and put it in the 8S2250 Nozzle

Holding Tool (P).

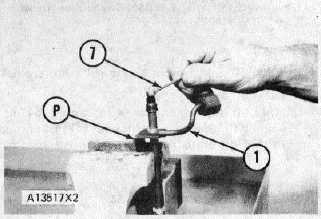

LOOSENING LOCKNUT

1. Fuel Injection nozzle. 7. 8H8502 Combination

Wrench. P. 8S2250 Nozzle Holding Tool.

2. Loosen locknut (5) that holds lift adjustment screw

(6). Turn lift adjustment screw (6) counterclockwise

two turns.

CAUTION

If the lift adjustment screw is not turned

counterclockwise two turns, the valve can be

bent or the seat for the valve can be damaged

when the pressure adjustment screw Is turned.

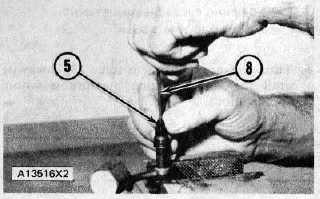

3. Hold lift adjustment screw (6) with a 5/64" hex

wrench (8) and remove locknut (5).

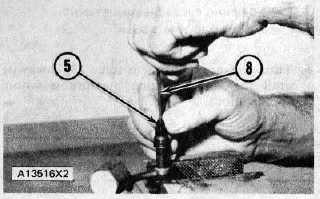

REMOVING LOCKNUT

5. Locknut (for lift adjustment screw). 8. 5/64" hex

wrench.

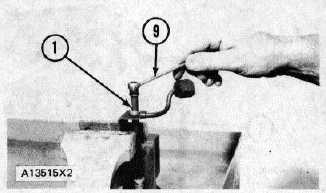

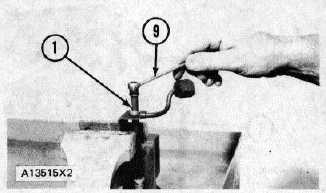

LOOSENING LOCKNUT

1. Fuel Injection nozzle. 9. 8H8505 Combination

Wrench.

4. Loosen locknut (2) that holds pressure adjustment

screw (3).

5. Put fuel injection nozzle (1) on the nozzle tester.

Turn pressure adjustment screw (3) clockwise with

5P4813 Socket (10). Each one-fourth of a turn will

increase the opening pressure approximately 250

psi (1720 kPa).

2-45