TM 5-3825-226-24

BASIC BLOCK

CYLINDER BLOCK

The cylinders are a part of the cylinder block. There are

no replaceable cylinder liners. The cylinders can be

machined (bored) up to .040 in. (1.02 mm) oversize for

reconditioning. The cylinders in the block are at a 90°

angle to each other. There are five main bearings in the

block to support the crankshaft.

CYLINDER HEAD

There is one cylinder head for each side (bank) of the

engine. One intake and one exhaust valve is used for

each cylinder. The valve guides are a part of the

cylinder head and can not be replaced. A valve seat

insert is used for the exhaust valve and can be

replaced. When the seat for the intake valve has been

machined to the limits given in the SPECIFICATIONS, it

can be bored (machined) for a valve seat insert.

PISTONS, RINGS AND CONNECTING RODS

The pistons have two rings which are located above the

piston pin bore. There is one compression ring and one

oil control ring. The oil ring is made in one piece and

has an expansion spring behind it. The compression

ring is also one piece and goes into an iron band that is

cast into the piston.

The piston pin is held in the piston by two snap rings

which go into grooves in the piston pin bore.

The connecting rod is installed on the piston with the

boss on the connecting rod on the same side as the

crater in the piston. The connecting rod bearings are

held in location with a tab that goes into a groove in the

connecting rod.

CRANKSHAFT

The force of combustion in the cylinders is changed to

usable rotating power by the crankshaft. The crankshaft

can have either six or eight counterweights. A gear on

the front of the crankshaft turns the engine camshaft

gear and the engine oil pump. The end play of the

crankshaft is controlled by the thrust bearing on No. 4

main bearing.

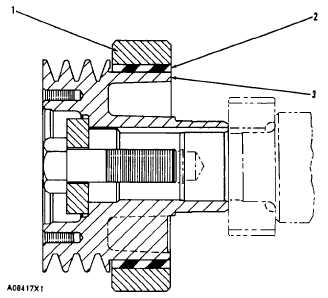

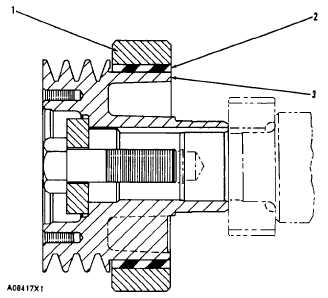

VIBRATION DAMPER

The twisting of the crankshaft, due to the regular power

impacts along its length, is called twisting (torsional)

vibration. The vibration damper is installed on the front

end of the crankshaft. It is used for reduction of

torsional vibrations and stops the vibration from building

up to amounts that cause damage.

The damper is made of a flywheel ring (1) connected to

an inner hub (3) by a rubber ring (2). The rubber makes

a flexible coupling between the flywheel ring and the

inner hub.

CROSS SECTION OF A VIBRATION DAMPER

1. Flywheel ring. 2. Rubber ring. 3. Inner hub.

2-18