TM 5-3825-229-14&P

6-4. CYLINDER HEAD AND VALVES (cont)

b. Cleaning and Inspection (cont).

(10) Inspect valve seats in cylinder head. Check angle of valve seats. Valve seat angle for exhaust valves is

440. Intake valve seat angle should be 290. If seat angles in head are not correct, grind seats and valves as

follows:

(a) Remove carbon from valve seat area. Using a valve grinding stone, grind intake valve seat to a 300 angle

with a uniform seat on the surface.

(b) Finish grind intake valve seat to a 29° angle with a fine stone and clean seat.

(c) Check intake valve face. Seat on valve must be 290 and have a uniform face.

(d) Refinish valve faces on a valve refacing machine to 29° angle.

(e) Check valve head depth in cylinder head with a depth gauge. Depth should be 0.0189 in. (0.48 mm). If

depth is not correct, regrind to correct depth.

(f) Use a dial indicator to check valve runout of valve seat in cylinder head. Runout must not exceed 0.0019 in.

(0.050 mm). If runout is excessive, regrind valve seat to meet specifications.

(g) Grind exhaust valve seats and valve faces in the same manner to a seat angle of 450.

(h) Exhaust valve head depth should be 0.264 in. (0.67 mm).

(i) Runout of exhaust valve seats must be 0.0019 in. (0.050 mm).

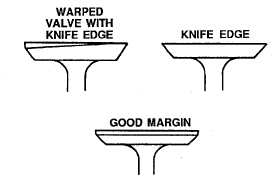

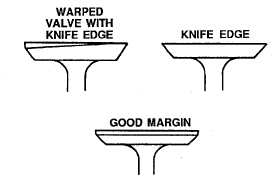

Checking Valve Head Seats

6-5