TM 5-3895-370-14&P

b. Cleaning/lnspection.

(1) Clean injector nozzle seats with nylon tube brush.

WARNING

Compressed air used for cleaning

purposes will not exceed 30 psi (207

kPa). Use only with effective chip

guarding and personal protective

equipment (goggles/shield, gloves,

etc).

(2)

Wash cylinder head in hot water and soap for 30

minutes. Rinse and use compressed air to dry.

(3)

Check cylinder head for nicks, erosion, cracks,

and other damage.

(4)

Polish gasket surface of cylinder head using 400

grit waterproof silicon carbide abrasive paper.

(5)

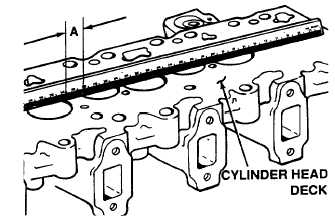

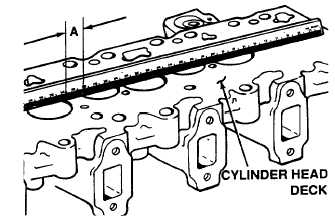

Check cylinder head deck for distortion as

indicated. Distortion can be no greater than

0.0039 in. (0.0991 mm) within a 2 in. (50.8 mm)

radius (distance A) or no greater than 0.003 in.

(0.076 mm) end to end.

(6)

Check valve guides in cylinder head for scuffing

or scoring. Ream valve guides to remove any

surface damage.

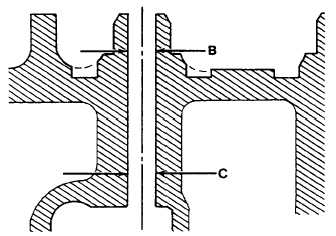

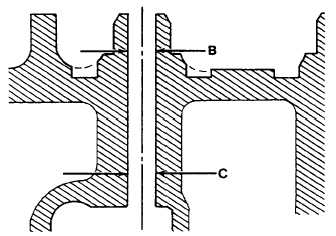

(7)

Measure valve guide bores at positions B and C.

Normal measurement is 0.3157 to 0.3185 in.

(8.0188 8.0899 mm). If less than normal, rebore

valve guide. If greater than normal, replace

cylinder head.

(8)

Clean valve heads with a soft wire wheel.

(9)

Clean and polish valve stem with crocus cloth.

Remark valves according to head location.

NOTE

When replacing old valves, remember

to mark new valves the same for

correct assembly.

(10)

Check for abnormal wear on valve heads and

stems. Replace valves that are bent or cannot

be ground.

5-263