TM 10-8110-201-14&P

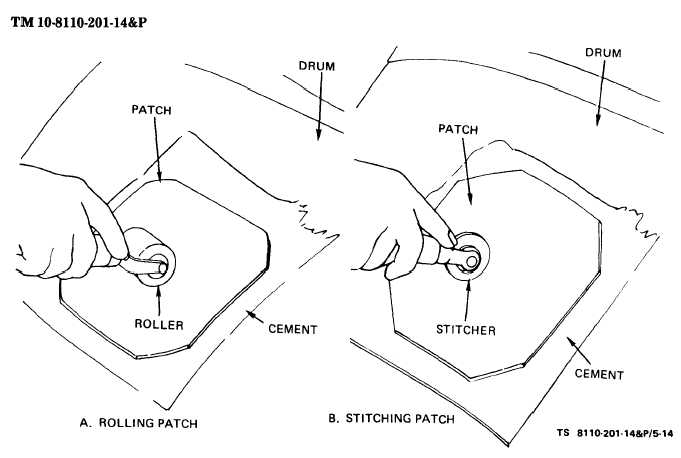

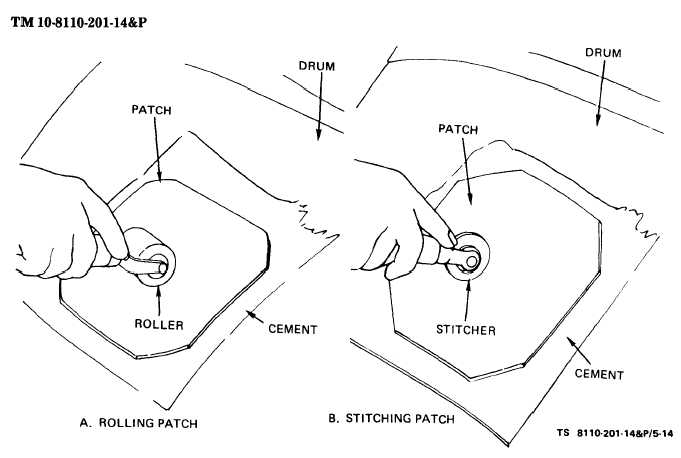

Figure 5-14. Rolling and Stitching Patch

(6) Apply one coat of 3985 cement to the re-

maining side of the second patch and one coat of

cement to the first (small) patch. Allow cement to

dry.

(7) Reactivate both cemented surfaces with

freshner No. C-3339 or MEK. Position the two

cemented surfaces together, centering the smaller

patch on the large patch. Roll and stitch

thoroughly.

(8) Apply two coats of 3985 cement to area

cleaned around break. Allow the cement to dry bet-

ween coats.

(9) Apply one coat of 3895 cement to the patch

assembly. Apply to the underside of patch (with

small patch affixed). Allow cement to dry.

(10) Reactivate both cemented surfaces with

freshner No. C-3339 or MEK. Position patch on

break and press in place. Roll and stitch

thoroughly.

(11) Apply one coat of 3985 cement around out-

side edge of patch assembly. Allow cement to dry.

c. Vulcanizing (Fuel Drums).

Prior to vulcanizing, aerate the interior

of the drum with compressed air and

check with an explosive meter (01575),

Model (05HCS) or equivalent.

(1) Position repair area in jaw

of cure unit so that repair area is

facing the heating element.

(2) Slip a sheet of RM58B cloth inside drum

immediately under liner patch. Place a second

sheet immediately over exterior patch. Place a pad

under the repair and close jaws of unit. Inflate unit

bladder.

(3) Cure for one hour and 15 minutes at 300° F

(149° C) and cool under pressure for 45 minutes.

(4) Deflate unit bladder and remove drum from

unit.

(5) Suspend drum by one end and inspect in-

terior and exterior of repaired area.

(6) Remove all foreign matter, dust, flakes,

etc., from drum interior with compressed air or

wash thoroughly and dry.

All data on pages 5-19 and 5-20, including Figure 5-15, deleted.

5 - 1 8