b.

On units equipped with conventional wet or dry charged batteries with removable vent caps, check the

electrolyte level frequently. Add clean, mineral-free or distilled water to bring the electrolyte in each cell

up to the level indicator.

4-9.6

Idle Control Circuit Protection.

4-9.6.1

The idle control printed circuit board and the throttle solenoid are protected by an automatic reset circuit

breaker CB1 located behind the right side panel.

4-9.6.2

Normally, this circuit breaker should not trip. However, if an arc is struck or the AUTO IDLE switch is placed

in the OFF position after the throttle solenoid has deenergized and the engine is slowing down, CB1 may trip. If this

occurs, wait approximately one minute before resuming operation.

4-9.7

Brushes and Slip Rings. (Figure 4-7) - Brush life is very good under normal operating conditions. The

brushes and slip rings should be inspected every six months or whenever excitation voltage is lost. Check for cleanliness

of the slip rings and freedom of motion of the brushes. If the welding generator has been operating under extremely

dusty or dirty conditions, increase the frequence of inspection.

a.

Under normal use the slip rings will discolor to a dark brown. If a buildup of brush material is noted, it

may be necessary to clean the slip rings. Use a 3/0 or finer sandpaper followed by a crocus cloth. Never use emery

cloth as part of the emery will embed itself into the rings and in turn destroy the carbon brushes.

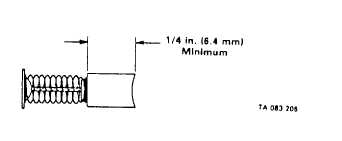

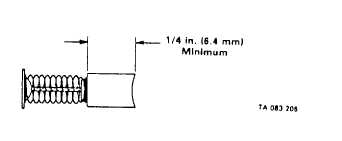

b.

Replace the brushes if they become chipped or broken or if less than 1/4 in. (6.4mm) of fresh material is

left.

Figure 4-7. Brush Replacement

4-9.8

Engine Speed Adjustments (Figure 4-8). The engine speeds have been factory adjusted and will not require

frequent readjustment. After tuning the engine, check the speeds with a tachometer. With no load applied, the power

speed should be 1860 rpm for 60 Hz. Models and the weld speed 3000 rpm. If necessary adjust the speeds as

described following.

4-24