NOTE

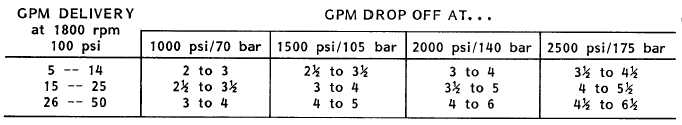

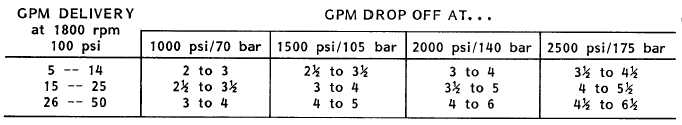

Pumps are generally tested to 2000 psi maximum.

NOTE

At test speeds other than 1800 rpm, gpm delivery will vary almost proportionately,

but the same (drop-off) figures should be used.

k. Be sure to run the pump in the direction for which it was designed and built. Driving pump in the wrong direction

will build up pressure behind shaft seal, damaging it and necessitating replacement.

l. After completing testing procedures, pump is ready for installation and immediate

duty operation on equipment. Again, it must be remembered that to prevent seizure, hot oil must not be fed into a cold

pump.

7-1.2 Fabricated Tools.

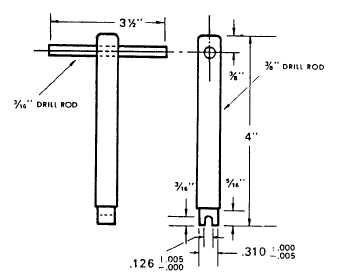

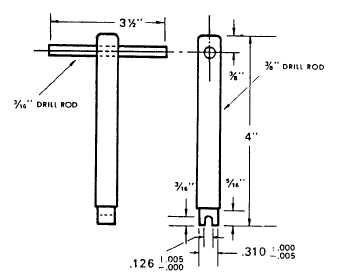

a. Check Valve Tool. The check valve tool is made from a 4 inch length of 3/8 inch drill rod. Refer to figure 7-1 to

fabricate this tool.

Figure 7-1. Check Valve Tool

7-2