AIR BRAKES - GENERAL INFORMATION

1.

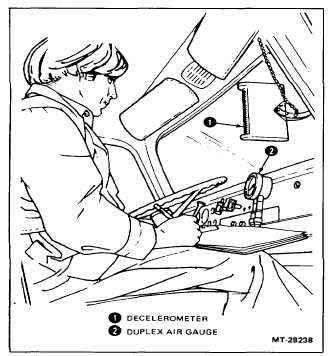

Mount a decelerometer (Figure 31) to the inside

windshield - as follows:

a.

Moisten the vacuum cups and press the

decelerometer assembly to the windshield

so it can be read by the observer.

b.

Loosen the bracket lower clamp nut and

adjust the decelerometer so that its sides

are-parallel to the direction of travel, then

tighten the clamp nut.

c.

Loosen the side adjusting clamp nut and

adjust the vertical position so that the fluid

registers zero when the truck is on level

ground, then tighten the clamp nut.

Figure 31 - Test Instrumentation (In-Cab)

2.

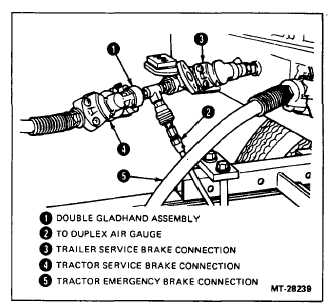

Install the single or duplex air test gauge (Figure

31) and connections as follows:

a.

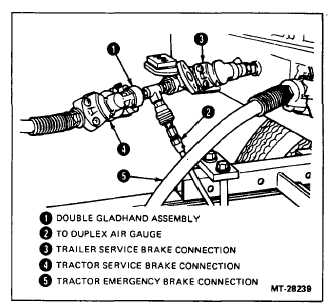

Install the double gladhand assembly in the

tractor to trailer service line (Figure 32).

b.

Mount the single or duplex test gauge in the

cab so it can be seen by both the driver and

the observer.

c.

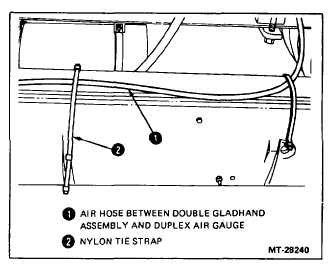

Connect an air hose between the double

gladhand assembly and the gauge.

Figure 32Double Gladhand Assembly

Installation

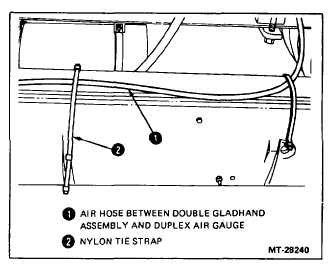

d.

Secure the air hose to the vehicle so that it

will not snag when the vehicle is turned (Figure 33).

Figure 33 - Gauge Test Hose Routing

3.

Record the following Preliminary Data (vehicle

information) on the Data Sheet (CTS-1033Y)

before initiating the test:

a.

Typical Weight (estimated) for normal

maximum highway operation.

b.

Test Weight (actual axle weight or best

estimate). The vehicle should be loaded to

the extent that wheel lockup will not occur

with a 276 kPa (40 psi) brake application at

a test speed of 64 kmh (40 mph).

CTS-4154Y - Page 32