AIR BRAKES-GENERAL INFORMATION

c.

Initial Test Speed - If other than the recom-

mended 64 kmh (40 mph). If speeds of 64

kmh are not permitted in the area chosen

for the test, the test speed for the snubs

can be reduced to 30 mph. Whatever

speed is used, it should be the same for

each of the checks noted below.

4.

Check the brake torque output of the tractor and

trailer in combination and individually as follows:

NOTE - An observer should be used to record all data for

these tatas. Only the SUSTAINED decelerometer

reading a should be recorded and not the peak readings

at the beginning and end of each step.

a.

Tractor-Traller Combination Torque Output

The

initial

step

in

evaluating

the

performance

of

a

tractor-trailer

Is

to

determine whether the combination

is

capable

of

operating

at

its

designed

performance level.

While

operating

the

tractor-trailer

combination in a suitable test area, make

three (3) stops from 64 kmh (40 mph) at

276

kPa

(40

psi)

brake

application

pressure.

Record

the

sustained

deceleration reading (to the nearest .5

ft./sec.2) for each stop in the appropriate

space on the Data Sheet. Determine the

average for the three readings.

b.

Tractor Torque Output

With the service brakes released, close the

shut-off cock in the double gladhand

connection between the tractor and trailer.

WARNING - SINCE CLOSING THE SHUT-

OFF

COCK

MAKES

THE

TRAILER

SERVICE

BRAKES

INOPERATIVE,

ALLOW

MORE

DISTANCE

FOR

STOPPING

THE

COMBINATION

VEHICLE. IF POSSIBLE, USE A NON-

PUBLIC AREA FOR CONDUCTING THE

TEST.

Again,

operate

the

tractor-trailer

combination, this time using the tractor

brakes only to make three (3) stops from 64

kmh (40 mph) at 276 kPa (40 psi) brake

application

pressure.

Record

the

decelerometer readings on the Data Sheet;

determine and record the average reading.

c.

Trailer Torque Output

With the service brakes released, open the

shut-off cock In the double gladhand

assembly.

Again,

operate

the

tractor-trailer

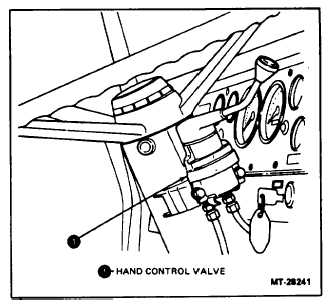

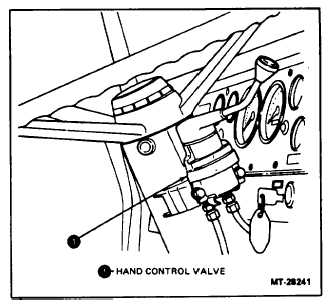

combination and, using only the trailer hand

control valve (Figure 34) make three stops

from 64 kmh (40 mph) at 276 kPa (40 psi)

and record the readings and average on the

Data Sheet.

NOTE - It may be helpful to preload the traller air

lines for smooth brake application and more

accurate test results. This Is accomplished by

maintaining vehicle speed while lightly applying

the hand control valve just prior to the test stop.

Figure 34 - Trailer Hand Control Valve

5.

Add the average deceleration reading for the

tractor to the average deceleration reading for

the trailer.

The sum should be within +.5 ft./sec.2 of the average

deceleration reading obtained from the combination test.

If not, the individual tractor and trailer torque output tests

must be rerun.

Evaluating the Performance of Tractor and Trailer

6.

From the test results, compute the Balance

Ratio using the following formula:

NOTE - Typical Weights In the formula are those

weights normally being carried by the vehicle. If

a realistic estimate cannot be made, it Is

recommended that the tractor and trailer (with

typical load) be weighed.

7.

Record the Balance Ratio on the Data Sheet. a If

the balance ratio is 1.00, the tractor-trailer

combination is in ideal torque balance.

CTS-4154Y - Page 33