AIR COMPRESSOR - MIDLAND BRAKE MODELS EL-1300, EL-1600

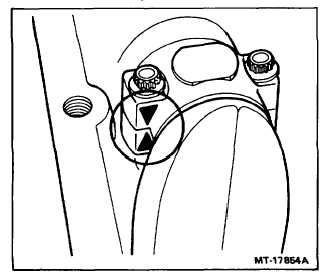

5.

Turn compressor assembly over and position

connecting rod on crankshaft journal making

sure that the inserts are in place. Install caps

and inserts matching arrows on bearing cap and

rod as shown in Figures 11 and 12.

Tighten connecting rod bolts according to listing

In TORQUE CHART in this Section. Use a 12

point 5/16 in. socket on connecting rod bolts.

Figure 11 - Piston and Connecting Rod Assembly

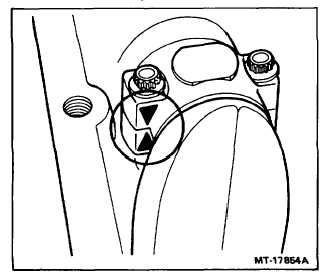

Figure 12 - Connection

6.

Install the second connecting rod assembly in

the same manner.

CYLINDER HEAD

NOTE - Refer to Figure 5 during the following

procedures:

1.

Turn cylinder head upside down and insert new

washers (Item 12), exhaust valve springs (Item

9), exhaust valves (Item 10), and exhaust valve

seats (Item 11). Tighten exhaust valve seats to

torque valve specified in TORQUE CHART In

this Section.

2.

With head still positioned upside down, Insert

new washers (Item 12), inlet valve seats (Item

16), inlet valves (Item 13), inlet valve springs

(Item 15) and inlet cages (Item 14). Inlet valves

and springs must be centered to insure the valve

is not tightened between inlet valve seat and

cage. Tighten valve cage to specified torque

valve using valve cage tool SE-2613 as shown in

Figure 6. Refer to TORQUE CHART in this

Section.

UNLOADER

1.

Install new O-ring seals between flanges on

unloader pins. (Refer to Figure 4.)

2.

Form a 14mm (9/16 in.) ball of lubricant around

O-ring seal. Use a silicone lubricant which is

intended for dynamic lubrication between oil

resistant rubber seals and metal parts, meeting

MIL-L-4343A

requirements.

Dow-Corning

Corporation #33 medium weight grease is

suggested. (For optional lubricant refer to

BRAKES-AIR,

COMPONENTS,

General

Lubrication Specifications, Item 3.

3.

Position unloader assemblies and springs in

bores of cylinder head.

4.

Place unloader gasket on unloader cover.

Assemble these two items as a unit compressing

the unloader springs and hold until the unloader

cover bolts and lockwashers or hardened plain

washers are installed.

5.

Tighten unloader cover bolts to about 1.1 N-m

(10 lb-in) torque.

IMPORTANT - Unloader

cover

bolts

should

be

tightened

to

torque

valve

after

cylinder

head

bolts

have

been

tightened to second step torque

valve.

CYLINDER HEAD TO CYLINDER BLOCK

Position new cylinder head gasket on cylinder block.

With gasket aligned, position cylinder head on block.

Insert the longest head Volt through the unloader cover

center hole; the other five head bolts through the

remaining holes. Tighten head bolts in the sequence

noted in Figure 13. This is a two step process: first,

tighten to the first torque valve noted in TORQUE

CHART; second, retighten to second valve noted in

TORQUE CHART.

Tighten unloader cover bolts to torque valve listed in

TORQUE CHART in this Section.

CTS-4077Y

Page 11