AIR COMPRESSOR - MIDLAND BRAKE MODELS EL-1 300, EL-1 600

REMOVAL AND INSTALLATION

WARNING - WHEN ANY COMPONENT IS SER- VICED

OR REMOVED FROM THE AIR SYSTEM, BE SURE TO

SET THE PARKING BRAKE AND/OR BLOCK THE

VEHICLE TO PREVENT IT FROM MOV- ING WHILE

ANY SERVICE IS BEING PERFORMED. REMOVAL

1.

Drain air pressure from main reservoir.

2.

Drain engine cooling system and cylinder head

of compressor if compressor is water-cooled.

3.

Disconnect all air, water and oil lines leading to

and from the compressor.

4.

Remove compressor mounting bolts and drive

belts as required.

5.

Remove compressor from engine.

6.

Use suitable puller to remove pulley or gear from

compressor crankshaft after removing crankshaft nut.

7.

Inspect pulley or gear and associated parts for

wear or damage. If any parts are found worn or

damaged, they must be replaced.

INSTALLATION

Installation of compressor is performed by reversing the

removal procedures. Items to be observed when

reinstalling compressor are:

Clean oil supply line so that oil will flow freely through the

line.

Be sure oil return line or passages through brackets are

clean and unrestricted so that oil can return to engine.

Always use a new mounting gasket and be sure oil holes

in gasket and compressor are properly aligned with oil

supply line.

Inspect drive pulley (gear) for water or damage. It should

fit securely on the crankshaft, contacting the shaft only,

not riding the key. Tighten drive pulley nut to

recommended torque, refer to SPECIFICATIONS in this

Section.

Insure that the air cleaner is clean and properly installed.

If air intake is connected to the engine air cleaner,

connections should be tight with no leakage.

Clean or replace any dirty, corroded, or damaged air or

water lines before connecting them to the compressor.

Use a new discharge fitting gasket.

Align compressor drive and adjust to proper belt tension.

Tighten mounting bolts to recommended torque, refer to

SPECIFICATIONS in this Section.

After compressor is installed, operate it and check for air,

oil or water leaks at connections. Be sure to check for

noisy operation.

DISASSEMBLY

The air compressor crankcase, cylinder block and

cylinder head are designed so that these basic

components may be assembled In various ways to meet

various Installation requirements. To guard against the

parts being assembled incorrectly, these parts should be

marked in some manner prior to disassembly.

AIR CLEANER

Some compressor installations do not have a separate

air cleaner. These models are equipped with a hose to

the engine air cleaner and only the hose disconnect will

be required.

To remove the air cleaner, remove the two bolts which

secure the air cleaner and manifold to the cylinder head.

Remove air cleaner and manifold as one unit from air

compressor.

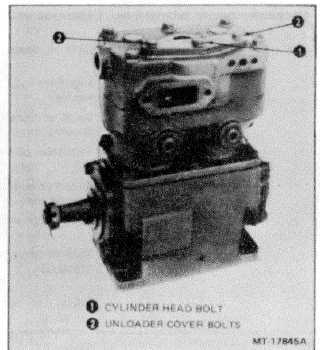

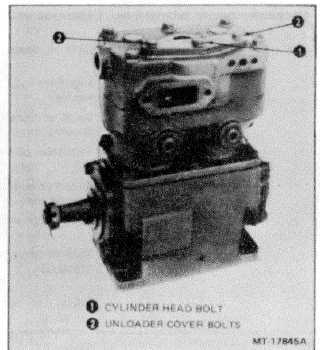

UNLOADER

1.

Bleed off main air reservoir. (For on vehicle

maintenance only.)

2.

Remove two hex head unloader cover bolts and

cylinder head bolt located in center of unloader cover

(Figure 3).

Figure 3 - Unloader Cover Removal

3.

Remove unloader cover. Unloader seal and end

of pin will protrude from head.

4.

Remove unloader pins with seals and unloader

springs (Figure 4). Discard seals and cover

gasket.

CTS-4077Y - Page 6