SERVICE MANUAL

DOUBLE CHECK VALVE

DESCRIPTION

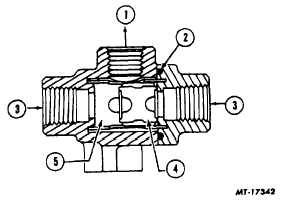

Double check valves or two-way check valves (Fig. 3)

are used in an air brake system where it is necessary to

automatically direct the flow of air pressure into a

common line from either of two other lines.

Fig. 3 Sectional View of Double Check Valve Shuttle

Type

1

Delivery

4

Shuttle Valve

2

"O" Ring

5

Shuttle Guide

3

Supply

OPERATION

As air pressure enters either end of the double .heck

valve (inlet port) the movable shuttle responds to the air

pressure and seals the line on opposite inlet port, but

permitting air pressure to ’low out the delivery (outlet)

port. The same action takes place if air pressure on one

side of shuttle is higher than that on the other side. It is

not necessary for the cavity of one side of shuttle to be

exhausted for valve to operate. Double check valves are

designed so it is impossible for shuttle to block outlet

port.

MAINTENANCE

Once each year or every 160,000 km (100,000 miles)

remove, disassemble, clean and inspect all parts. Install

new parts if signs of wear or deterioration are apparent.

SERVICE CHECKS

Due to the various applications of double check valves it

is best to bench test the valve using two separately

controlled air supplies and connected to inlet ports.

1.

Install an accurate test gauge in outlet port or in

a line from outlet port.

2.

Apply and release air to one inlet port and note

that gauge registers application and release.

3.

Repeat application and release of air to other

inlet port.

4.

Leakage check is performed at inlet ports by:

a.

Disconnecting line from one inlet port.

b.

Applying air to other inlet port. If soap solution is

used to check leakage, leakage should not

exceed 25.4 mm (1 in.) bubble in 5 seconds.

c.

Repeat step "b" by applying air to other inlet port

while checking opposite inlet port for leakage.

5.

If check valve does not meet requirements, it

should either be replaced or disassembled and

repaired using new parts.

DISASSEMBLY

1.

Remove end cap from valve.

2.

Remove O-ring.

3.

Remove shuttle (piston) and guide.

CLEANING AND INSPECTION

1.

Clean all metal parts in cleaning solvent.

2.

Inspect

all

parts

for

signs

of

wear

or

deterioration. Replace all parts not considered

serviceable.

3.

Replace all rubber parts.

REASSEMBLY

1.

Install shuttle guide and shuttle.

2.

Position new O-ring in end cap.

3.

Install end cap.

4.

Perform operating and leakage as described in

SERVICE CHECKS.

PRESSURE PROTECTION VALVE

DESCRIPTION

The pressure protection valve is designed to close off air

supply to any air operated device as long as the air

supply is below a specified rating.

The rating of the valve used in the FMVSS-121 air

system is 448-517 kPa (65-75 psi).

CTS-4079-CHAPTER III -

PRINTED IN UNITED STATES OF AMERICA

PAGE 4