SERVICE MANUAL

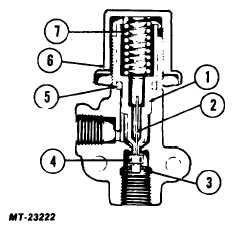

Fig. 7 Cross Section of Pressure Limiting Valve

1

Piston

5 Piston "O" Ring

2

Valve Guide Wire

6 Exhaust Vent

3

Inlet Valve Spring

7 Pressure Regulating

4

Inlet & Exhaust

Spring

Valve

If pressure in the delivery line exceeds the pressure

setting of the pressure limiting valve, the force exerted by

the air pressure below the piston will be greater than the

spring force above the piston. The piston will move up

from the exhaust valve, permitting air to pass by the

exhaust valve, through the hollow piston and valve guide

and escape through the slot in the adjusting cap. When

the force of the spring above the piston overcomes that

of the air pressure below the piston, the exhaust valve is

seated, and the pressure in the delivery line is the same

as the setting of the pressure reducing valve.

MAINTENANCE

Every 6 months or 80,000 km (50,000 miles). Connect a

test gauge to the delivery line and observe at what

pressure the inlet valves closes, which is the delivery

pressure. If the pressure delivered by the pressure

reducing valve varies more than plus or minus 35 kPa (5

psi) from the pressure setting of the pressure reducing

valve, the valve should be adjusted. The lock nut should

be tightened after each adjustment and lockwire seal

replaced if used. Every year or every 160,000 km

(100,000 miles) perform the SERVICE CHECKS.

SERVICE CHECKS

Operating Check

Connect an accurate test gauge to the delivery line and

observe what pressure the inlet valve opens which is the

delivery pressure. If delivery pressure varies more than

35 kPa (5 psi), adjust the valve to the specified setting.

To raise the delivery pressure the adjusting cap should

be turned clockwise. Tighten locknut after each

adjustment and replace lockwire and seal if used.

Leakage Check

No leakage is permitted at the exhaust vent in the slot of

the adjusting cap when making the operating check.

Leakage at this point would indicate a leaking piston O-

ring or a leaking exhaust valve seat.

If the pressure limiting valve does not function as

described or leakage is excessive, it is recommended

that it be replaced.

REMOVE

Apply parking brakes or block wheels to prevent vehicle

from moving.

Drain service and isolated reservoirs.

Disconnect air lines from the pressure reducing valve.

Loosen valve mounting bolts and remove.

REINSTALL

Check and clean air lines to valve.

Mount valve securely with bolts and lockwashers.

Reconnect lines to the valve.

Disassembly and reassemble of Pressure Limiting Valve

is not recommended as it is serviced as a complete

assembly.

CTS-4079 - CHAPTER III

PRINTED IN UNITED STATES OF AMERICA

Page 7