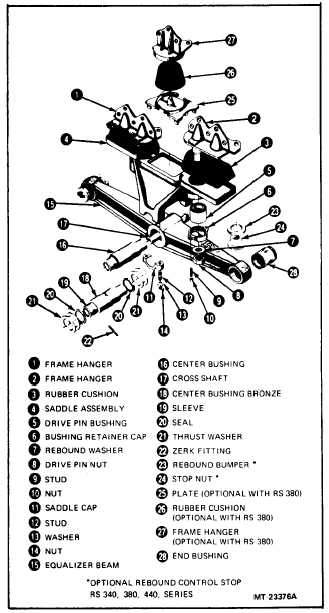

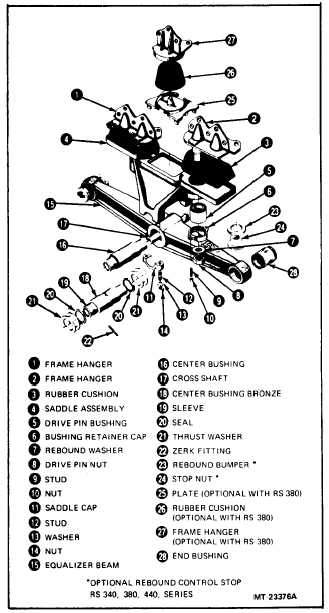

EQUALIZING BEAM SUSPENSION (HENDRICKSON)

c.

Assemble the frame brackets to the saddle by

inserting the drive pins through the load cushions

and the drive pin bushings.

d.

Install drive pin nuts and washers. Washers are

installed with flange down. Tighten nuts snug.

If frame hangers were removed, tighten nuts to

specified torque after hangers

have

been

assembled to chassis frame.

e.

Assemble

the

preassembled

saddles,

load

cushions and frame hangers to the chassis

frame. Install mounting bolts, lock washers and

nuts.

f.

Tighten mounting bolt nuts to specified torque.

(See SPECIFICATIONS.)

g.

Tighten drive pin nuts to specified torque. (See

SPECIFICATIONS.)

2.

Assemble cross tube and equalizer beams to

axle assemblies, Figures 14 and 15.

CAUTION -- WHEN ASSEMBLING SUSPENSION,

EQUALIZER BEAM AND MOUNTING NUTS, AND

EQUALIZER BEAM SADDLE CAP MOUNTING

NUTS SHOULD HAVE FINAL TORQUE APPLIED

WITH WHEELS OF VEHICLE ON GROUND.

WARNING -- THREE TYPES OF EQUALIZER

BEAMS ARE UTILIZED IN THE MANUFACTURING

OF INTERNATIONAL TRUCKS EQUIPPED WITH

EQUALIZER BEAM SUSPENSIONS.ALTHOUGH

THE APPEARANCE OF THE EQUALIZER BEAMS

IS

SIMILAR,

THERE

IS

A

SUBSTANTIAL

DIFFERENCE IN THE MATERIAL OF WHICH THEY

ARE MANUFACTURED.

THE MATERIALS OF THE EQUALIZER BEAMS

INVOLVED ARE ALUMINUM, CAST STEEL AND

NODULAR IRON.ALUMINUM AND CAST STEEL

EQUALIZER BEAMS ARE MANUFACTURED SUCH

THAT THEY CAN BE STRESSED IN EITHER

DIRECTION. NODULAR IRON EQUALIZER BEAMS

ARE MANUFACATURED SUCH THAT THEY CAN

BE STRESSED IN ONE DIRECTION ONLY. THUS

IT

IS

IMPERATIVE

THAT

NODULAR

IRON

EQUALIZER BEAMS BE INSTALLED WITH THE

CORRECT SIDE UP.

TO AID IN IDENTIFICATION AND FACILITATE

INSTALLATION OF NODULAR IRON BEAMS, AN

ARROW AND THE WORD UP HAVE BEEN

MOLDED ON THE SIDE OF NODULAR IRON

BEAMS. ALSO, REINFORCING GATE PADS HAVE

BEEN DESIGNED INTO EACH END AND MIDDLE OF

THE TOP SIDE OF NODULAR IRON BEAMS.

NODULAR IRON EQUALIZER BEAMS MUST BE

INSTALLED WITH GATE PADS ON TOP SIDE OF

BEAM AND THE ARROW MOLDED ON THE BEAM

SIDE POINTING UPWARD.

Figure 15 - Rubber Cushion Type Suspension

CTS-4169 - Page 11