SERVICE MANUAL

CONNECTING RODS, PISTONS, RINGS & SLEEVES

Section 5

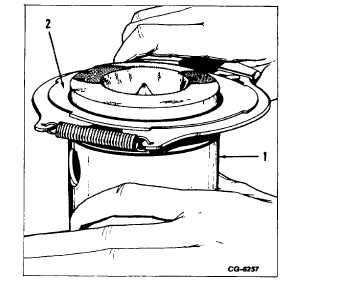

Figure 14. - Checking Piston Ring Gap

1. Piston ring

2. Feeler gauge

3.

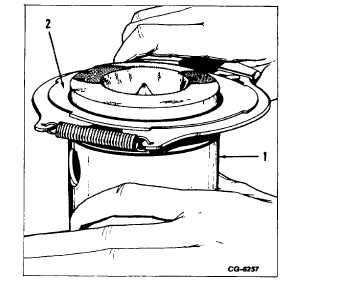

Install new rings in the piston grooves with a

suitable ring installing tool as shown in Fig. 15.

a.

The No. 1 (compression ring) will have the

word “TOP” stamped on the ring.

b.

The No. 2 (intermediate ring) will be

marked “TOP”, “UP” or with a “PIP” on

the top side of the ring.

Check TOP and INTERMEDIATE Piston compression

ring groove widths for wear.

Figure 15. - Installing Piston Ring using Piston Ring

Expander Tool

1. Piston

2. Piston Ring Expander Tool

NOTE: A new piston groove wear measuring Tool

No. 3020 has been developed to accommodate the

complex configurations of International Harvester’s

technologically advanced pistons.

Tool Description: The Tool, No. 3020, consists of two

.0900 in. gauge pins and two 0.1150 in. gauge pins

mounted on springs (Fig. 16). The .0900 in. gauge pins

are used to measure piston groove wear on pistons with

half

keystone

INTERMEDIATE

compression

ring

grooves. The 0.1150 in. gauge pins are used to

measure piston groove wear on pistons with full keystone

TOP or IN-TERMEDIATE compression ring grooves.

The following checks are made to be sure that the

compression rings (keystone) fit are correct and not

carrying the piston load. If the measurement over gauge

pins is not within specifications, replace old pistons and

rings with new.

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 16