SERVICE MANUAL

GENERAL

Section 1

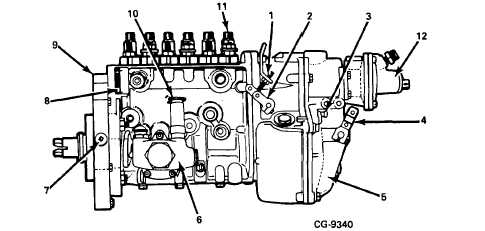

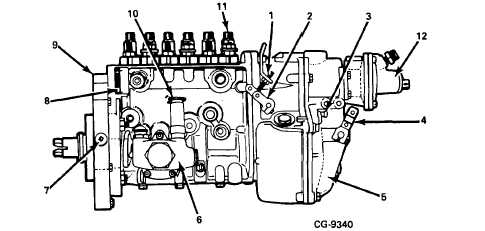

Figure 1. Robert Bosch Model MW Fuel Injection Pump

1.

Shut-off Stop Screw

5.

RQV Governor Housing

9.

Mounting Adapter

2.

Shut-off Lever

6.

Fuel Supply Pump

10.

Hand Priming Pump

3.

High Idle Stop

7.

Timing Pointer Plug

11.

Plunger

4.

Throttle Lever

8.

Serial Number Plate

12.

Aneroid

DESCRIPTION

The Robert Bosch Model PE(S)-6MW Injection Pump is

used on the International DT-466C diesel engine.

The injection pump is an in-line, plunger type, with an

individual plunger and barrel pumping element for each

engine cylinder. The injection sequence is 1,5, 3, 6, 2, 4.

The injection pump assembly incorporates mechanical,

flyweight type RQV variable speed governor.

The pump throttle lever and the high-speed stop screw

are located on the left side of the governor assembly.

The fuel shut off lever is also located on the left side of

the governor.

The injection pump is located on the left side of the

engine. High pressure lines connect the pump to the

nozzles. Operating and service instructions for the

nozzles are given in CGES-200-2 Service Manual.

IDENTIFICATION

Identification of injection pump and governor can be

made by referring to two nameplates, one on the rear of

the governor housing, and one on the front top left of the

injection pump (Figure 2). The nameplate on the rear of

the governor gives the IH part number of the complete

pump and governor assembly and the Robert Bosch

governor number, size and rating. The nameplate on the

left side, gives the Robert Bosch pump description

number.

OPERATING PRINCIPLES

The injection pump is the in-line type with an individual

plunger and barrel pumping element for each engine

cylinder. Each plunger stroke is constant, but its

effective pumping (metering) stroke is variable and is

controlled by the positioning of a common control rack

connected through linkage to the governor and the

vehicle’s throttle lever.

The individual plunger and barrel pumping elements

receive fuel at supply pump pressure from the injection

pump housing fuel gallery, and forces it under very high

pressure through the injection nozzles into the engine

combustion chamber.

The injection pump plungers are moved by tappet

assemblies which ride on the lobes of the injection pump

camshaft. The injection pump camshaft is timed to the

engine to inject fuel into each cylinder at the proper time.

CGES-375

Printed in United States of America

Page 1