SERVICE MANUAL

GENERAL

Section 1

Supply Pump With Hand Priming Pump

The piston-type supply pump (6, Figure 1) is activated by

the eccentric on the injection pump camshaft and serves

as a mount for the hand priming pump (10, Figure 1).

Since all fuel entering the injection pump must be filtered

to ensure long pump life, the hand priming pump should

be used when changing fuel filters. Always install the

fuel filters "dry" and use the hand pump to fill the filters

and bleed air from the fuel system.

Aneroid Assembly

Exhaust smoke levels during engine acceleration are

controlled by using an aneroid (12, Figure 1). The

aneroid limits fuel delivery during acceleration until the

turbocharger speed is sufficient to provide adequate air

for complete combustion. An external line connects the

intake manifold to the aneroid to allow manifold pressure

to activate the aneroid. A leak in the aneroid diaphragm

or intake manifold to aneroid line will cause the injection

pump to stay in the "cutback" position, and reduce

engine power.

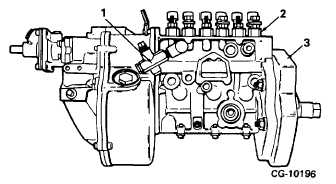

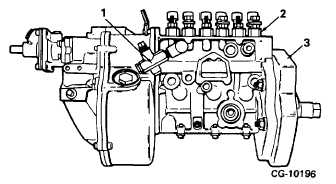

Fuel Return Valve

A fuel return check valve is mounted to the injection

pump housing (1, Figure 6) and all fuel that is not

injected passes through the check valve and then

through a special orificed rubber hose. The function of

the fuel return check valve is to provide

Figure 6. Right Side View of Injection Pump

1.

Fuel Return Valve

2.

Delivery Valve Holder

3.

Drive Gear

a positive seal to prevent fuel from draining out of the

pump housing when the engine is stopped. The fuel

return check valve opens at approximately 18 psi.

Therefore, total fuel flow through the injection pump

housing is controlled by the orifice in the rubber hose as

long as the supply pump pressure is above 18 psi. After

the fuel flows through the orifice, the fuel pressure drops

from the intermediate pressure ahead of the orifice to

low pressure (Figure 4).

GOVERNOR

The mechanical flyweight governor (5, Figure 1) which is

mounted on the injection pump, is the variable speed

type, identified by the manufacturer as ROV 350-1200

(or -1300). The 350-1200 (or -1300) designation refers

to the injection pump speed range in which the governor

functions. This corresponds to 700 to 2400 (or 2600)

engine RPM, since the pump camshaft rotates at 1/2

engine speed. Figure 7 illustrates a typical cut-away

view of the RQV governor

Figure 7. Cut-Away View of Governor Assembly

1.

Stop Shackle

7.

S-Plate

2.

Rack Link

8.

Guide Pin

3.

Control Rack

9.

Adjusting Pin

4.

Governor Springs

10.

Guide Lever

5.

Bell Crank

11.

Rocker Arm

6.

Sliding Block

12.

Aneroid

CGES-375

Printed in United States of America

Page 5