COOLING SYSTEM

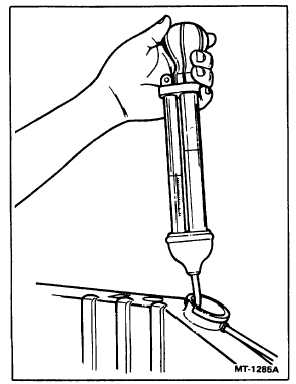

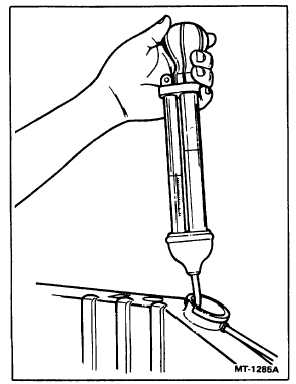

Hydrometers

Hydrometers (Figure 5) are used to test the freezing

protection of an anti-freeze solution and work on the

principle of specific gravity or weight of the anti-freeze

solution. They are simple to use, If used in the proper

manner. When using the hydrometer, the solution must

be at least 44°C (110F). The temperature and level

must be noted correctly and the float must be able to

move freely. Read only the hydrometer scale

corresponding to the type anti-freeze solution in the

radiator. Keep hydrometer clean inside and out and treat

it with the same care as given any other precision

instrument.

Figure 5. - Using Hydrometer to Test Anti-freeze

Solution

SE-2384 Pressure Tester

This tester (Figure 6) consists of a heavy duty pump

complete with adapters for remotely applying pressure to

the cooling system at the radiator fill neck. The pump is

equipped with a pressure gauge, manual pressure relief

valve and hose assembly, with twist-on clamp bracket to

receive the adapters. The adapters can be quickly

attached together for a small or large filler neck either

with a shallow or deep neck.

Figure 6. - SE-2384 Cooling System Pressure Tester

SE-2395 Anti-Freeze and Battery Tester

This tester (Figure 7) is designed for quick and accurate

checking of anti-freeze protection and battery specific

gravity readings. Coolant may be checked hot or cold

with a minimum amount of coolant or battery acid

required. Operating instructions are included with the

Figure 7. - SE-2395 Anti-Freeze and Battery Tester

TROUBLESHOOTING

CAUSES OF COOLANT LOSS

Leaks and Seepage

May be either external or internal.

External leaks easy to locate, may occur at radiator,

heater, water pump, core plug hole, hose connections,

radiator cap, drain cocks and gaskets.

Internal leaks are more difficult to locate since these

leaks occur at cracks and faulty head gaskets. Internal

leaks are indicated by a decrease in coolant level and

the presence of coolant in crankcase.

CTS-4181

Page 10