TM 5-3825-226-24

2.

Fasten .25 in. (6.4 mm) I.D. (inside dimension)

hoses to the bleed screws that lets the air out.

Put the loose end of the hoses into ajar that has

enough fluid in it so that the end of the hoses

are under the surface of the fluid.

3.

Push the brake pedal down and release it

several times until the indicator rods make a

shorter stroke.

4.

Keep the brake pedal down and look at the

indicator rod.

5.

Open the bleed screws that lets the air out and

look at the fluid that comes out of the hoses.

Close the bleed screws when the indicator rod is

extended 1.44 in. (36.6 mm).

6.

Do Steps 3, 4, and 5 until the fluid that goes out

of the hoses has no air bubbles.

7.

Fill the reservoir to .50 in. (12.7 mm) from the

top of the reservoir when necessary.

8.

If necessary do the above procedure for the

water distributor.

ELECTRIC WARNING SYSTEM

NOTE

Before any test is made of the

electric warning system, check all

electrical connections and grounds

to assure good contact.

Start the engine and allow the air system pressure

to build up to cutout pressure and shut off the engine.

Turn the disconnect switch ON.

Slowly let the air pressure out by pushing down on

the brake pedal. Note the air pressure shown on the

gauge at which the buzzer begins to sound. This should

be at approximately 60 psi (415 kPa).

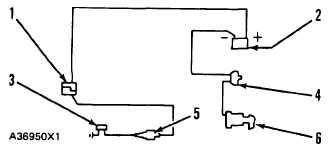

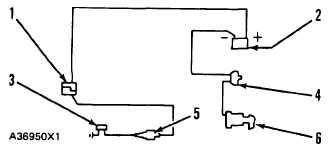

ELECTRIC WARNING SYSTEM

1. Pin connector. 2. Ammeter. 3. Low air pressure

warning buzzer. 4. Circuit breaker. 5. Low air pressure

buzzer located under the dash. 6. Starter switch.

If the buzzer does not begin sounding in the correct

pressure range, check continuity of the normally closed

pressure switch. The switch should be closed. If the

switch is good, check the buzzer. If either is defective,

install a new component.

CONTROL VALVE FOR PARKING BRAKE

Start the engine and let the air pressure go up to

cutout pressure. Stop the engine and push the knob of

the control valve IN. Let the air pressure out of the

reservoir by pushing the foot pedal down again and

again. Read the pressure on the test gauge at which the

knob comes out and the emergency brake goes ON.

The knob must come out at 40 + 5 psi (280 + 35 kPa).

If the knob does not come out, and valve has a

defect, install a new valve.

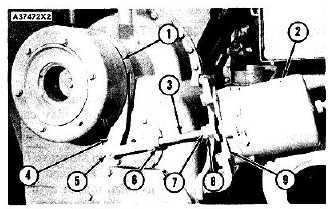

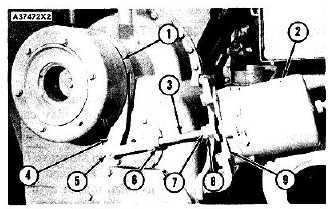

Make a full extension of pull rod (3) from brake

chamber (2). Use 75 psi (520 kPa) (minimum) air

pressure in chamber (2) if available. If no air pressure is

available, loosen locknut (7) and turn nut (8) clockwise

on pull rod (3) until nut makes contact with plate (9).

Turn nut (8) more so pull rod (3) moves to the left, out of

chamber (2). This action will cause compression of the

spring inside chamber (2) and release the parking brake.

Make the adjustment to rod end (5) so it will connect

to brake lever (4) when lever (4) is moved in the

direction of chamber (2). Move lever (4) enough so the

brake shoes start to make contact with the drum (1).

Make the connection and tighten locknut (6). Turn nut

(8) to a position of 1.25 in. (31.8 mm) from plate (9) and

tighten locknut (7).

ADJUSTMENT OF THE PARKING BRAKE

1. Brake drum. 2. Brake chamber. 3. Pull rod. 4. Brake

lever. 5. Rod end. 6. Locknut. 7. Locknut. 8. Nut. 9.

Plate.

2-142