TM 5-3825-226-24

BASIC BLOCK

When honing cylinder blocks, maintain the

specific dimensional surface finish and cross hatch

tolerances to obtain satisfactory oil control. The

tolerances specified are virtually the same as those

used for original bore finish at the factory, and can be

obtained with an automatic honing machine such as the

Sunnen CK-10. This machine has been evaluated and

found to give satisfactory results.

Due to the cost of suitable honing equipment, it

may be more expedient to have the honing done by a

shop equipped with a Sunnen CK-10 or equivalent.

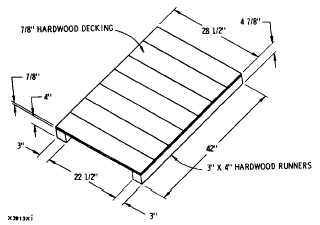

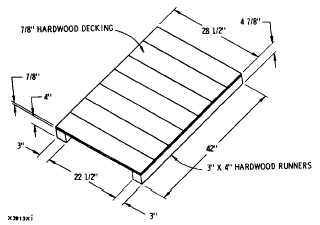

TRANSIT PREPARATION

The following Steps can prevent damage to the

block in transit to a shop.

1.

Completely disassemble, but do not clean block.

The residual oil on the surface will prevent rust.

2.

Enclose the block in an industrial plastic bag

and position it with the oil pan surface on a

suitable wood pallet or equivalent. Dimension

of a suitable wood pallet are shown.

TRANSPORTING PALLET

3.

Cover the block with 1/2 in. (12.7 mm) thick

plywood or equivalent, and band block to the

pallet.

4.

Follow

similar

instructions

when

block

is

returned. To prevent rust, the block should not

be cleaned after honing, the film of honing oil

provides ample protection from rusting.

NOTE:

If blocks are to be stored for any

length of time, clean and anti-rust

after honing.

CLEANING PROCEDURE

After

honing

is

completed,

and

before

assembling the engine, the cylinder block must be

cleaned and prepared according to the following

instructions.

1.

If

not

previously

removed,

the

camshaft

bearings must be removed to permit thorough

cleaning of the oil passages. To remove the

bearings, see the topic CAMSHAFT BEARINGS

REMOVAL AND INSTALLATION.

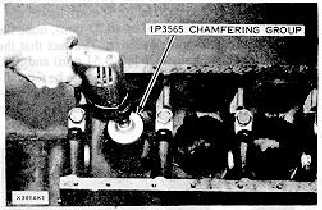

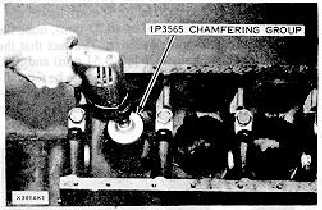

2.

Use 1P3565 Chamfering Group, remove the

sharp comer at the bottom of the cylinder bores

as shown. This is essential to prevent scuffing

the piston skirts. The chamfer should be

approximately 10° x .09 in. (10° x 2.3 mm).

CHAMFERING BORE

CAUTION

Avoid damage to the cylinder bore

surface or any other parts.

3.

Using the 1P5580 Brush Group and a strong

detergent

and

water

solution,

clean

the

following. areas of the block.

A.

Main oil gallery and supply passage. Use

the IP5572 or 1P5573 Brush and stroke

several times while rotating the brush.

B.

Camshaft bearing oil passages. Use the

1P5571 Brush and stroke several times

while rotating the brush.

C.

Cylinder bores. Use the 1P5574 Brush

and stroke each bore for one minute while

rotating the brush at 1000 rpm.

3-366