TM 5-3825-229-14&P

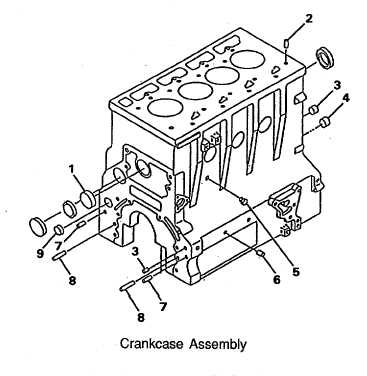

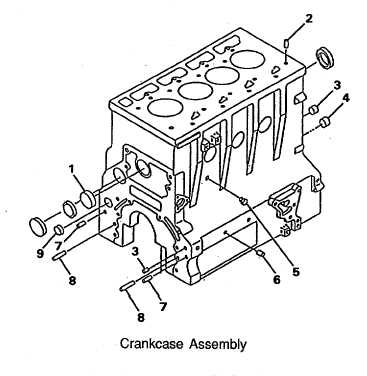

6-15. ENGINE CRANKCASE (BLOCK) (cont)

c.

Repair (cont).

WARNING

Wear protective goggles when using the cleaning solvent. Avoid contact with the eyes.

If contact occurs, flush eyes with cold water for 5 minutes and seek immediate medical

attention. Dry cleaning solvent (PD-680) is both toxic and flammable. Avoid prolonged

breathing of vapors. Avoid skin contact. Use only in a well-ventilated area. Keep away

from open flame. Flash point of solvent is 138°F (590C).

(c) Mix a solution of one part SAE 30W engine oil (OE/HDO) and one part cleaning solvent.

(d) Soak the hone brush in the solution to provide lubrication and aid in the honing process.

(e) Operate the drill and hone to provide the drill speed of 300 to 400 RPM. Slide hone

up and down complete length of cylinder bore.

(f)

Complete strokes should be about one stroke per second. Stop honing action to check

deglazing process. A fast, even cross hatch pattern on the cylinder walls should be

obtained in 20 to 30 seconds.

(g) Mix a strong solution of hot water and detergent. Clean the bores with the solution.

Use clean water to rinse solution from crankcase after cleaning. Use compressed air

to blow the surface dry after rinsing. Wipe all surfaces of cylinder dry with clean rags.

6-52