TM 5-3895-370-14&P

(12)

Slowly move pump transmission control lever (14) forward (FWD) to increase pump rate to 25 GPM.

(13)

Refer to Testing Spraybar for Circulation (para 2-21) to test spraybar for adequate material flow.

(14)

When spraybar is adequately warmed to the temperature of the material, move pump transmission control

lever (14) to neutral with the pump rate at 0 GPM.

(15)

Distributor is ready for operation. Refer to Table of Contents (page 2-1) for desired procedures.

2-21. TESTING SPRAYBAR FOR CIRCULATION.

a.

Introduction. The spraybar can become

clogged with material. Before operating spraybar,

perform the following test while circulating bituminous

material

through

system.

Refer

to

Circulating

Bituminous Material (para 2-20).

b.

Testing Spraybar for Circulation.

NOTE

· To ensure accuracy of this test,

open only two spraybar valves; one

at each end of spraybar.

· This procedure is also used during

spraybar suckback procedures to

allow air to enter spraybar.

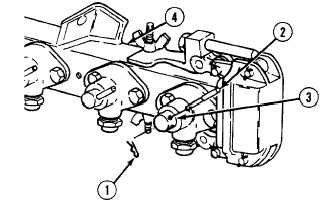

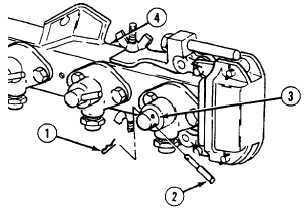

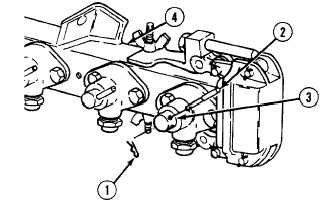

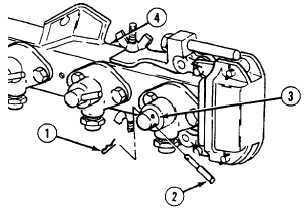

(1)

Remove hair pin (1) and pin (2) from spray

nozzle (3) on spraybar (4).

(2)

Insert pin (2) in spray nozzle (3) 90° out

from original position.

(3)

Insert hair pin (1) in pin (2).

2-47