CAUTION:

DO NOT Use water or oxygen for blowing out. The use of oxygen, especially, is

dangerous as the possible presence of even a minute quantity of oil may cause an

explosion.

Make certain that all gas is discharged from hoses then rewind hose on reel or rack and be sure horn valve is in its closed

position. See "After Fire Has Been Extinguished".

INSTRUCTIONS FOR REMOVAL OF CYLINDER

These instructions are to be carefully observed in the order given below when any cylinder or group of cylinders is to be

removed at any time.

CAUTION:

When removing charged cylinders, always disconnect the discharge heads first.

This will eliminate the possibility of discharging the carbon dioxide, with possible

injury to personnel.

1. Remove discharge beads from all cylinder valves by loosening mounting nuts (right-hand thread). 0n two, or more,

cylinder installations, swing discharge head and loop away from cylinder and allow to hang.

2. Remove all control heads from the cylinder valves. To do this, loosen mounting at (right-hand thread)

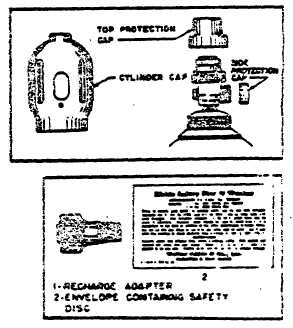

3. Screw large top protection cap to threads on top of cylinder valve. Cap control head outlet by screwing on side

protection cap.

4. Remove cylinder strap.

5. Remove cylinder. It is recommended that the cylinder cap be screwed on, to prevent damage to cylinder valve during

removal. (This cap is not included in the empty weight of the cylinder.)

RECHARGING INFORMATION

Kidde cylinders should be recharged with "bone-dry”

carbon dioxide. This can be done at any recharging

station, see "Kidde System" or "Walter Kidde Sales

Agency” in your telephone directory.

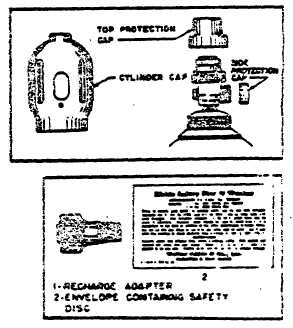

Recharge adapter part number 933537 is required in the

recharging of an empty of partially filled cylinder. For

safety discs order part number 902048 for cylinders

marked ICC-3A-1800 or ICC-3A-2015 and part numbers

903664 for cylinders marked ICC-3A-2300.