TIMING CASE AND DRIVE - K.5

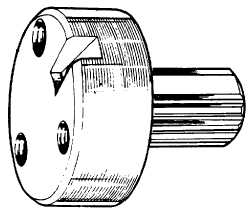

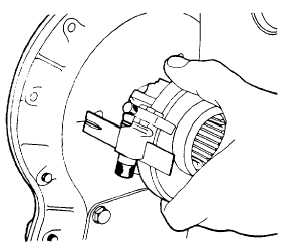

Fig. K.8.

Adaptor PD67B-1.

will ensure that all backlash is taken up at T.D.C.

Refit valve spring cap and collets.

2.

Fit adaptor PD67B-1 (see Fig. K.8) to the fuel

pump gear so that dowel of gear locates in slot

of adaptor and shaft of adaptor is towards rear

of engine. Secure adaptor to gear using gear

securing setscrews.

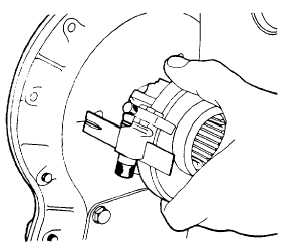

Fig. K.9.

Marking Scribed Line on Rear of New Timing Case.

3.

Release screw (5) of timing tool MS67B (see Fig

N.10) and remove splined shaft.

4.

Ensure slotted pointer (2) of timing tool is

positioned with slot to front of tool and

chamfered sides of slot outwards. At this stage,

slotted edge of pointer should be kept well back

from front of body. Ensure that flat of washer

fitted behind pointer securing screw (3) is

located over pointer.

5.

Release the bracket locking screw (4) and set

bracket so that the chamfered edge is in line

with the relevant engine checking angle (see

Page B.11).

6.

Pressing fuel pump gear and adaptor towards

rear, with the fuel pump gear timing mark

located correctly with the idler gear timing mark,

locate splined shaft of adaptor into timing tool

with master spline engaged and adaptor shaft in

timing tool with rear face of adaptor abutting

front face of timing tool.

7.

Move tool forward, complete with gear so that

register of tool locates in pump aperture of

timing case. If pointer is 180° out, then engine is

on wrong stroke and tool should be removed

and engine set on correct stroke.

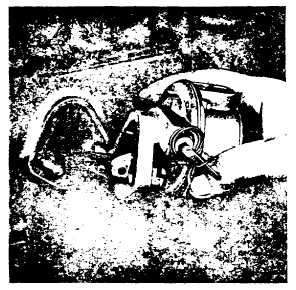

Fig. K.10.

Removing the Fuel Lift Pump.

8.

Slide slotted pointer forward to reach rear face

of timing case and lock in position.

9.

Take up backlash by turning tool against normal

direction of rotation (shown on pump nameplate)

and mark the scribed line on the rear of the

timing case to coincide with the centre of the slot

in the pointer (see Fig. K.9).

10.

Remove tool and adaptor from fuel pump gear

and fit fuel pump to engine as detailed on Page

N.6.

To Remove the Camshaft and Tappets

Camshaft end float is controlled by a thrust plate

located in a recess machined in the front face of the

cylinder block. The plate is dowelled to