RECONDITIONING BRAKE DRUMS AND SHOES

DRUM BRAKES

INSPECTION OF DRUMS

The friction surface of brake drums must be smooth, true

and concentric. Make certain with a visual check that

drums are not barrel shaped, bellmouthed, scored or

eccentric.

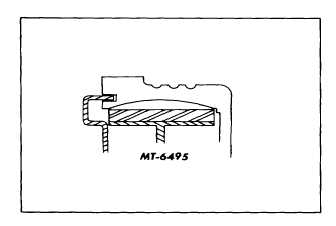

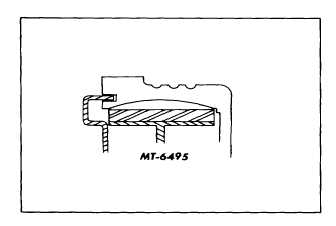

Hard or chill spots, Figure 1, in brake drum may produce

pedal pulsation and roughness or brake surge. If these

effects are present, drum should be replaced.

Figure 1 - Hard or Chill Spotted Drum

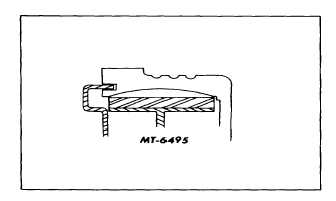

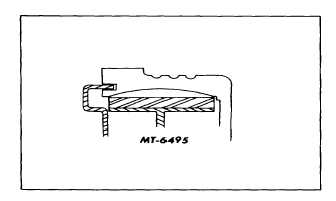

A

barrel

shaped

drum

(Figure

2)

results

from

overheating. If this barrel shaped condition is not

corrected, the braking surface is reduced and uneven

lining wear results.

Figure 2 - Barrel Shaped Drum

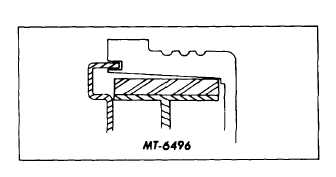

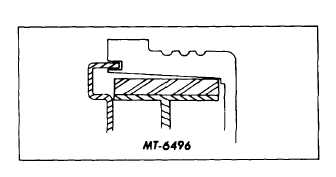

Extreme pressure which over a period of time will create

a bellmouthed drum as shown in Figure 3. Brake linings

on a bellmouthed brake drum will make contact only on

the inner surface of the drum. In addition to cutting the

braking surface to a minimum, it will also cause uneven

and rapid wear.

Figure 3 - Bellmouthed Drum

Scored drums are the result of worn linings to the point

where the drum-to-shoe contact is made or an

accumulation of small steel particles imbed themselves

in the brake lining (Figure 4). The steel particles form a

tough scale which is sometimes harder than the drum.

As a result, deep grooves are formed in friction surface

of drum.

Figure 4 - Scored Drum

Brake drum scoring never improves but continually gets

worse until both lining and brake drum are useless.

Attempting to reline brakes without turning scored brake

drum surface will quickly destroy new lining and make

effective braking impossible.

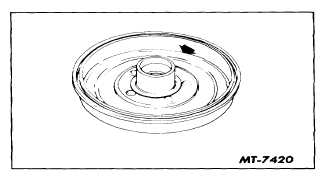

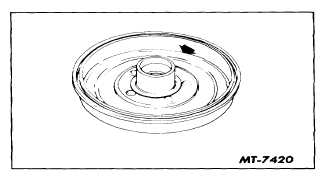

Check inner side of drum surface for tool marks to

determine if drum has been previously reconditioned,

Figure 5. If so, an oversize lining may be required.

Figure 5 - Check Brake Drum for Tool Marks

CTS-4082B - Page 3