VI. STEERABLE DRIVE END ASSEMBLY

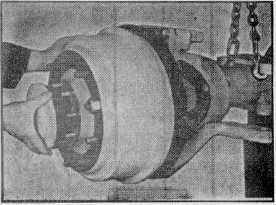

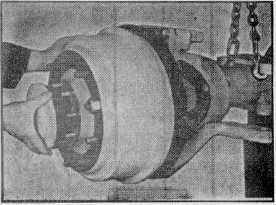

Fig. 38

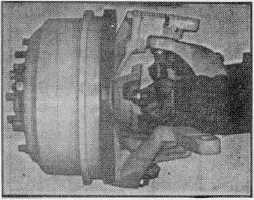

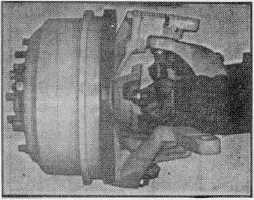

Fig. 39

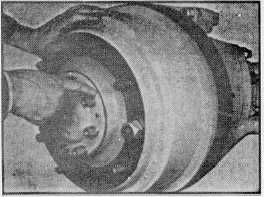

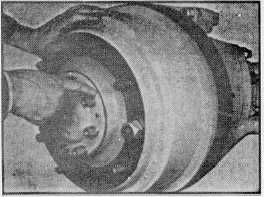

Fig. 40

J.

Universal Joint Assembly

Install the universal joint cross and bearing assembly

with two bolts in each of the bearing caps. (See figs. 27

and 20). Rotate the wheel hub to rotate the universal

joint while the end is turned against the steering stop and

check for positive clearance. (See fig. 9).

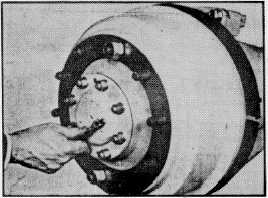

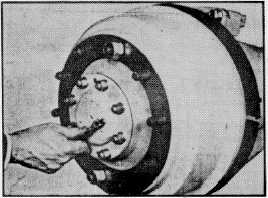

Fig. 41

K.

Brake Actuator Chamber Installation

If not already on the assembly, add the brake

actuator chamber. Assemble a collet nut on the actuator

chamber tube so that the tapered part of the nut will fit

into actuator. Screw the actuator chamber into the

actuator until the tube is tight against the wedge stop

washer. Tighten the collet nut securely (150 ft. lbs.

torque).

L.

Steering Arm Assembly

Install the steering arm and upper kingpin bearing

cap. Note that the short studs are used on the outboard

end when installing the steering arm and the long studs

on the inboard end. Use flexloc nuts on the studs. The

cap is held in place with bolts and lockwashers.

M. Tie Rod Assembly

Install the steering connecting tie rod. Tighten the

castle nuts to the specified torque and use new cotter

pins.

N.

Final Assembly

1.

Make adjustments as described in Section IIl.

2.

Lubricate and add lubricants as described in

Section II.

3.

Install wheels and tires. Torque wheel nuts to

specifications.

4.

Lower the vehicle to the ground and road test.

-19-