SERVICE MANUAL

CRANKSHAFT, MAIN BEARINGS, FLYWHEEL & CRANKCASE

Section 6

CLEANING, INSPECTION & REPAIR

CLEANING

Clean the Crankshaft and Main Bearings as follows:

1.

Clean all parts with non-caustic cleaning solvent.

2.

Dry with compressed air.

3.

Clean all the crankshaft internal oil passages of any

dirt or sludge that may have accumulated. Run a

stiff wire brush through the oil passages to loosen

the deposits, then wash the passages and external

surfaces of the crankshaft thoroughly with fuel oil.

Blow the passages and external surfaces dry with

compressed air.

Clean the Flywheel and Ring Gear as follows:

1.

Wash the flywheel and ring gear in non-caustic

solvent.

2.

Dry with Compressed air.

Clean the Crankcase as follows:

1.

During overhaul it is best to clean the crankcase

in a chemical “hot tank.” This removes all

carbonous material and mineral deposits that

collect in the cooling passages.

2.

Clean all lube oil passages, thoroughly.

3.

Remove gallery plugs and swab with a brush

and solvent. (Reseal all plugs upon installation).

4.

Clean all threaded holes with a tap of

appropriate

size

and

blow

clean

with

compressed air.

INSPECTION AND REPAIR

Inspect the Crankshaft and Main Bearings as

follows:

1.

Visually inspect the bearings for wear and evidence

of uneven bearing support. If such evidence is

found, examine the bearing caps and supporting

surfaces of the crankcase for high spots and burrs.

2.

Visually inspect the crankshaft journals for scoring.

3.

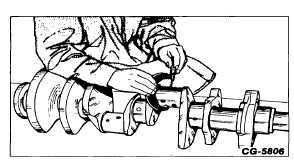

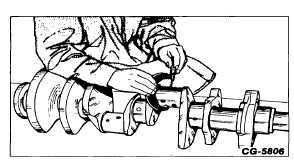

Measure the diameter of each journal using

a micrometer as shown in Fig. 11.

Measure each journal at two points, at right

angles to each other. Move the micrometer

over the entire width of the journal. Limits

of:

85.705 mm

(3.3742 in.)

85.738 mm

(3.3755 in.)

must be observed.

Figure 11. - Measuring the Crankshaft Journals

4.

Check HARDNESS, on every journal which

incurred a bearing failure or shows evidence of

overheating, as follows:

a.

Using a Rockwell Hardness Tester, check

at least three locations.

NOTE: Fillet hardened shafts should be checked as

close to the fillet as possible. Non-fillet hardened

shafts should be checked at least 13 mm (1/2 inch)

from the fillet.

b.

Check rod journals at top, bottom and one

other location. (Top and bottom determined

with journal at TDC).

c.

Minimum hardness:

D-312, D and DT-360,

D and DT-414, D and

30 RC

DT-436 non-fillet

hardened shafts.

D, DT and DTI-466

45 RC

fillet hardened shafts.

If any reading is below the minimum

hardness, REPLACE the crankshaft.

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 9