SERVICE MANUAL

TIMING, GEAR TRAIN & FRONT COVER

Section 7

6.

If the injection pump gear was removed install it

as follows: (For engines equipped with Robert

Bosch Model MW Fuel Injection pump)

a.

Be sure that engine crankshaft timing is set

at specified static timing prior to going any

further.

b.

Using

drive

gear

bolts

and

washers,

loosely install’ injection pump drive gear to

injection pump meshing it with the idler

gear (1, Fig. 27b). Make sure drive gear is

positioned in gear slots (Fig. 27c) so it

allows for adjustment.

c.

Align timing pointer (1, Fig. 27a) with timing

mark (2, Fig. 27a) by rotating injection

pump clockwise (as viewed from drive gear

end).

NOTE: For engines equipped with Robert Bosch

Model MW Fuel Injection Pump the timing pointer is

located on the injection pump mounting adapter and

the timing mark is located on the drive hub.

d.

Holding the pump shaft with a socket wrench (3,

Fig. 27b) torque drive gear bolts to 47 N•m (35

Ibf-ft).

e.

Rotate engine crankshaft counterclockwise 900

then rotate clockwise until pump timing pointer

and timing mark align.

f.

Observe engine to injection pump timing on

crankshaft pulley (Fig. 27d). Refer to

specifications (introduction) for correct alignment

(or see Chart 1, Section 11, Page 16).

7.

If the tachometer drive gear was removed,

proceed as follows: (UTDS* Model 100 Fuel

Injection Pump)

a.

Insert the gear onto the dowel.

b.

Slip the spacers over the mounting studs or

bolts.

c.

Place the thrust plate over the studs and gear.

d.

Install and tighten nuts to 27 N•m (20 Ibf-ft)

torque.

8.

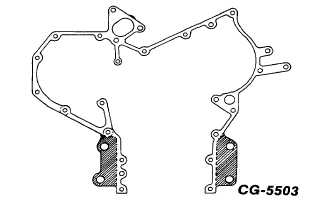

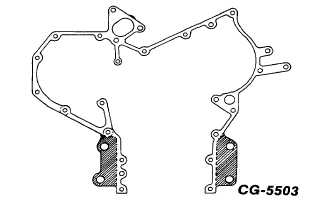

Using a new gasket, install the crankcase front

cover.

-Full Front Cover-

(See Fig. 5)

a.

For front covers with "ears" install the gasket as

shown in Fig. 28. DO NOT remove ears

(shaded areas).

Figure 28. - Front Cover Gasket (Rear View)

- Earless Front Cover -

(See Fig. 6)

b.

When the gasket (Fig. 28) is used on

"earless" front cover applications, install

the gasket and front cover then remove the

ears (shaded areas on Fig. 28).

NOTE: If the "EARS" are removed prior to

installation, gasket misalignment may result:

NOTE: Improper front cover installation will result in

cover distortion or loose engine mounting bolts.

*United Technologies Diesel Systems

(formerly AMBAC)

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 15