SERVICE MANUAL

WATER PUMP, THERMOSTAT & IDLER PULLEYS

Section 9

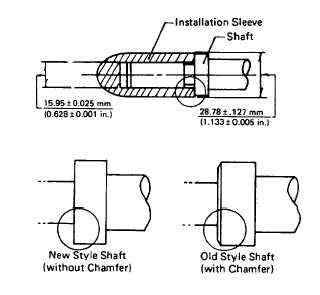

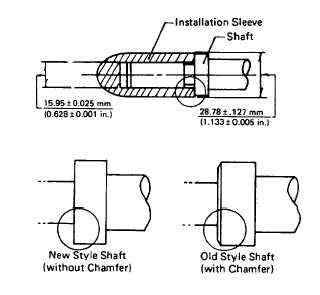

4.

Lightly lubricate seal surface of shaft and

O.D. of shaft installation sleeve with

grease* and install shaft into front of pump

with installation sleeve (Fig. A).

IMPORTANT: The shaft installation sleeve (Fig. A)

can be used with both old and new style water pump

shafts but MUST DEFINATELY be used with the new

style shaft (Fig. A). Installing the new style water

pump shaft ,without the shaft installation sleeve

could cause rear seal damage and/or displacement.

The shaft installation sleeve can be fabricated

locally.

Figure A. Shaft Installation Sleeve and Old vs. New

Style Water Pump Shaft

5.

Remove shaft installation sleeve.

6.

Grease* rear roller bearing outer race and press

into housing against shoulder.

7.

Install spacer (9).

8.

Press in outer race of front bearing and make

sure the outer bearing races and spacers are

bottomed.

*Lubricating Grease per EMS B27-5004, Type I - Use

Amoco Rykon Premium Grease No. 2 Color Red.

9.

Install spacers (8 and 12).

10.

Fill cavity between spacers with 17cc (.6 oz.) of

grease*.

11.

Prepack front roller bearing inner race assembly

with grease*. Support shaft at impeller end and

press inner race assembly until it bottoms on

shaft.

12.

Install spacer (16) and snap ring (7).

13.

Pack spring area of front seal (10) full of grease*

and lubricate seal lip with grease*. Install front

seal into housing against snap ring.

14.

Lightly lubricate seal surface of wear sleeve (14).

Install wear sleeve.

15.

Install hub (15) on shaft.

16.

Install nut (13) according to the following:

a.

If a flange nut is used apply engine oil to

threads. Torque to 237 N•m (175 Ibf-ft).

b.

If a regular nut is used add Loctite #242 to

threads. Torque to 203 N•m (150 Ibf-ft).

Torque shaft by internal hex while holding

nut.

17.

Install coolant seal (4) in bearing housing.

IMPORTANT: An "O" ring is necessary on coolant

seal used with new style bearing housing which has

a groove provided (Fig. 23a). With old style bearing

housing which has no groove an "O" ring MUST

NOT be used on the coolant seal. Instead apply

Permatex #3 to seal O.D. before installing (Fig. 23b).

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 14