SERVICE MANUAL

WATER PUMP, THERMOSTAT & IDLER PULLEYS

Section 9

CLEANING, INSPECTION AND REPAIR

CLEANING

Clean the Fan Idler Pulleys as follows:

1.

Wash all parts in cleaning solvent to remove all

grease.

2.

Dry with compressed air.

3.

DO NOT spin bearing cones with compressed

air.

INSPECTION AND REPAIR

Inspect and Repair the Fan Idler Pulley with Front

and Rear Roller Bearing as follows:

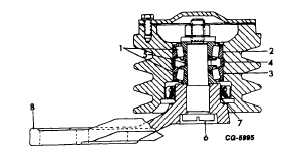

(Fig. 29)

1.

Visually inspect the bearing cones (1, Fig. 29) for

binding,

roughness,

overheating

or

other

damage. If the cones require replacement it is

necessary to also replace the bearing cups (2

and 3) and spacers (4 and 5).

2.

Visually inspect the bearing cups (2 and 3) inside

of the pulley hub for roughness, overheating or

other physical damage. If the cups require

replacement, replace the cones (1) and spacers

(4 and 5) also.

3.

Using a slide hammer with proper expander,

remove bearing cups from pulley hub. Remove

spacer (4) from groove in pulley hub. Check

bearing bore of hub for wear or damage.

Replace hub if necessary.

4.

Check pulley shaft (6) for cracks or thread

damage. If necessary to replace, cut it out of the

bracket (8). DO NOT damage the bracket.

Figure 29. - Fan Idler Pulley Assembly

1.

Bearing cone

5.

Spacer

2.

Bearing cup

6.

Pulley shaft

3.

Bearing cup

7.

Wear sleeve

4.

Spacer

8.

Bracket

REASSEMBLY AND INSTALLATION

Reassemble and Install the Fan Idler Pulley (with

Front and Rear Roller Bearing) as follows:

1.

Press shaft (11, Fig. 30) into bracket (12) until

head bottoms in bracket counterbore.

2.

Install spacer (7) in the groove of pulley hub.

3.

Press front bearing cup (6) into pulley bore until

it bottoms on spacer (7).

4.

While supporting the pulley by the front bearing

cup, press rear bearing cup (8) into pulley bore

until it bottoms on spacer (7).

5.

Install oil seal (9) (with lip facing out) flush with

pulley bore.

6.

Prepack area between seal (9) and bearing cup

(8) with I.H. 251H-EP grease.

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 19