SERVICE MANUAL

ROBERT BOSCH MODEL MW INJECTION PUMP

Section 11

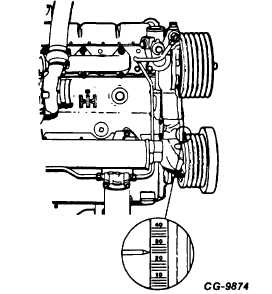

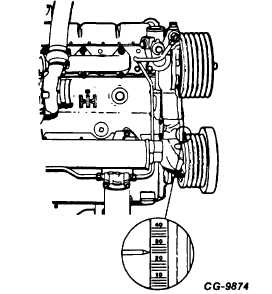

11. Verify alignment of pump timing pointer to hub mark

through mounting adapter opening (Figure 23).

Rotate pump drive hub as required for proper

alignment. Torque pump drive gear bolts to 35 ft-lbs.

(47 N•m). Observe engine to injection pump timing

on pulley (Figure 24). Refer to Chart 1 on Page 19,

this section, for correct timing.

Figure 24. - Engine to Injection Pump Timing on Pulley

12. Install drive gear access cover.

13. Install lubricating oil line to injection pump.

14. Install fuel supply, fuel return and high pressure

injection pipes with all clamps and brackets. Clean

inside of each injection pipe with filtered air before

assembling to injection pump and nozzles.

INJECTION PUMP DELIVERY VALVE HOLDER

MUST BE HELD WITH A WRENCH TO PREVENT

MOVEMENT WHEN HIGH PRESSURE PIPING IS

BEING INSTALLED (refer to Figure’20).

15. As applicable, install electric shutoff assembly,

ground and power supply wire.

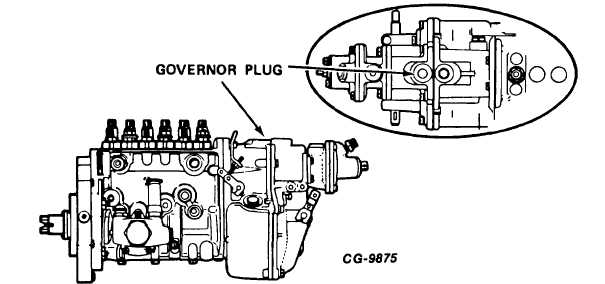

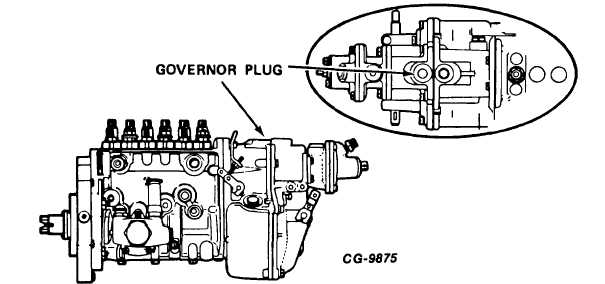

16. Add minimum of one pint of engine oil to governor

through the upper governor housing plug (Figure 25).

Because injection plug is splash lubricated, engine

oil must be added to a replacement pump.

17. Install throttle cable or linkage to outer control lever.

Adjust throttle cable or linkage so tang in outer

control lever is in "override position." At "override"

lever tang will be approximately half way from center

of control lever to end of slot.

Figure 25 - Governor Housing Plug

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 19