SERVICE MANUAL

5.

Clamp flange in vise or use flange holder tool and

tighten output shaft end nut to specified torque. (See

"Torque Chart".)

Assemble Inter-Axle Differential To Intermediate

Case

1.

Position diff lock clutch shift collar on input gear (Fig.

46).

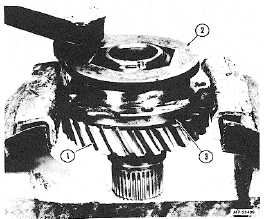

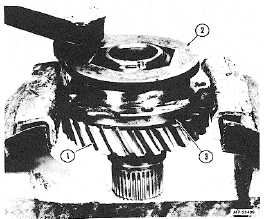

Fig. 45. Tightening Input Gear Bearing Retaining Nut

(RA-351, 355 Shown RA-341 Similar)

1

Input Gear

2

Bearing Nut Wrench

3

Bearing Retainer

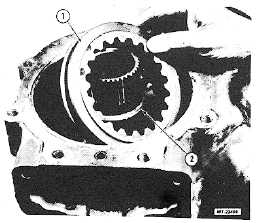

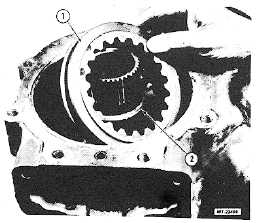

Fig. 46. Installing Clutch Shift Collar

1

Clutch Shift Collar

2

Input Gear

2.

Apply a 3 mm (1/8") bead of gasket sealant on

intermediate case.

3.

Position

inter-axle

differential

assembly

on

intermediate case (Fig. 47). Make sure teeth on rear

of differential mesh with clutch shift collar previously

installed.

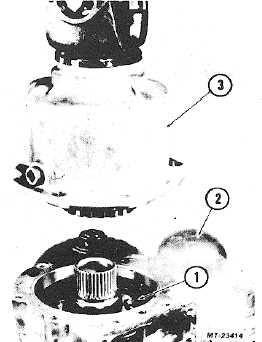

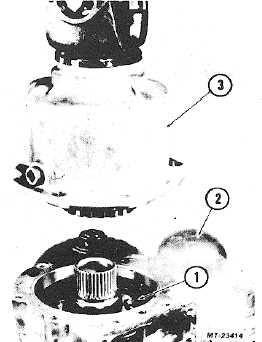

Fig. 47. Installing Inter-Axle Differential

1

Clutch Shift Collar

2

Intermediate Case Assembly

3

Inter-Axle Differential Assembly

4.

Install diff cover bolts. Tighten to specified torque.

(See "Torque Chart".)

Install Intermediate Case And Inter-Axle Differential

To Diff Carrier

1.

Apply a 3 mm (1/8") bead of gasket sealant on

intermediate case.

2.

Position intermediate case assembly on diff carrier

(Fig. 48). Make sure flats on end of idler shaft index

with flats in carrier.

3.

Install intermediate case bolts. Tighten evenly to

specified torque. (See "Torque Chart".)

CTS-4044

PRINTED IN UNITED STATES OF AMERICA

Page 25