BEST AVAILABLE COPY

2.

Operate control hand lever to check for adequate

clearance. If additional clearance is required at

full forward proceed as follows:

(a)

Set control hand lever either side of neutral.

Loosen setscrew (19) with a 5/32" Allen wrench

and remove control hand lever from shaft.

(b)

Replace control hand lever on shaft to provide

desired clearance and tighten setscrew.

3.

Apply forward and reverse decal (32) to the control

head adjacent to neutral position of control hand

lever.

NOTE: Before stripping of protective backing paper

from decal, clean the control surface

thoroughly.

6. Connect Clutch and Throttle Cables to Engine

1. Follow the procedure outlined in the Throttle and

Clutch Connection Kit Installation Instructions

supplied with each kit.

7. Final Adjustment

1.

Operate the control head hand lever several times.

The engine clutch lever and the control clutch arm

(14) MUST coincide at forward, neutral and

reverse detent positions.

2.

The

engine

clutch

lever

position

must

be

determined only by the control cable and should

not be jammed against forward or reverse stops.

Adjust the shift cable terminal (at the clutch end

first) until detents are properly synchronized.

3.

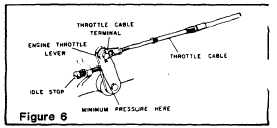

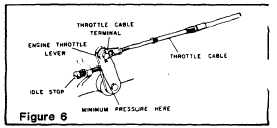

Operate the control hand lever through the

complete operating range. The carburetor throttle

lever should rest lightly against its idle stop when

the control hand lever is at neutral. At neutral

detent, pull out hand lever hub and move thru

forward range. Return to neutral and hand lever

should snap back in place. Excessive pressure of

the carburetor throttle lever against its idle stop will

prevent the control hand lever from moving freely

in and out at the neutral detent. To remedy this,

adjust the engine throttle cable terminal so the

control cable will move the engine throttle lever

against its idle stop with minimum pressure. (See

Figure 6).

CAUTION

THROTTLE

CABLE

MUST

BE

DISCONNECTED

FROM

MOTOR

BEFORE

MAKING

MOTOR

IDLE

ADJUSTMENTS. Adjustment of the

motor idle while the throttle cable is

still connected to motor, may cause

a jamming action against the idle

stop. As a result, control may not

function properly.

4.

The carburetor throttle arm should be at full travel

position when the control hand lever is at full

forward throttle. In reverse, only limited movement

of the carburetor throttle arm is available. When

the throttle cable is correctly adjusted, the engine

speed will remain at idle while the control is

shifted, and will increased only when the hand

lever is moved beyond the (UNREADABLE

TEXT)

NOTE

Throttle cable requires free back-and-

forth swing clearance two to three

feet below the control head housing

for smooth operation.

Figure 6

5.

Tighten all cable supports.

6.

Check all screws, nuts, cable connections and

cable terminal for tightness.

7. Water test the boat. The control hand lever should

operate freely with light hand pressure. Any

stiffness or binding in the operation of the hand

lever can usually be traced to:

(a)

Excess number of bends in cable runs.

(b)

Sharp bend in the cables too close to control

head.

(c)

Bends smaller than the recommended minimum

radius of 8”.

(d)

Tight or misaligned engine linkage.

(e)

Cable compressed too tightly by cable supports.

(f)

Engine clutch lever jamming its limit stops at

forward and/or reverse.

8. Operation

1.

Adjust

the

engine

for

smooth

idle,

as

recommended by the manufacturer.

2.

For starting or warm-up, place the control in

neutral detent position and pull out the hand lever

nub to disengage the shift mechanism allowing the

lever to be moved forward or backward to advance

the throttle. When warm-up is completed, return

the lever to neutral detent. The hand lever will

automatically snap into the operating range. (If

lever does not engage into operating range when

returned to neutral, check for excessive pressure

of the engine throttle lever against its idle stop).

3.

When operating the “MT-2" control, shift crisply out

of neutral into forward or reverse, but do not shift

too quickly from forward into reverse. Stay in the

neutral or idle position until the boat has lost most

of its headway before completing the shift to

reverse.

9. Maintenance

1.

CORROSION PROTECTION

For maximum protection, especially in salt water

areas, wipe metallic parts, such as screw heads,

cable sleeves, etc., with oil or light grease.

Chrome plated hand lever and covers should be

washed with fresh water and waxed regularly.

2.

MECHANICAL PERFORMANCE

(a)

Periodically check control mechanism for loose

fastenings and signs of wear or moving parts,

particularly the cable terminals. Lubricate

moving parts with a good quality marine grease.

(b)

Periodically

examine

cables

and

engine

connections for signs of physical damage.

(UNREADABLE TEXT)