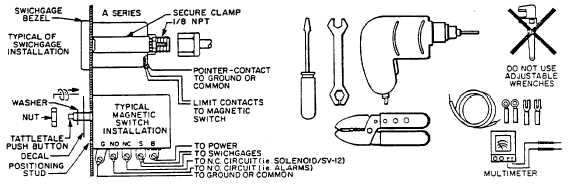

TYPICAL INSTALLATION

SWICHGAGEâ INSTALLATION (Refer to drawing)

1. Secure the SWICHGAGE' in the panel, using the clamp and

nuts provided.

NOTE: Be sure the SWICHGAGEâ and

panel are grounded.

2. Connect the pressure or vacuum line, using a 1/8 NPT

adaptor at the SWICHGAGEâ end.

NOTE: Be sure that pressure line is clean

and that pipe dope or teflon used on

fittings does not block the line.

3. If not in a prewired panel, wire the limit switchless) to a

Murphy magnetic switch or relay.

NOTE: Pilot duty (2 A @ 30 V resistive)

contacts must be protected from high

current: disconnect power during wire-

up.

TEST: Start equipment: wait for pointer to lift off low contact:

check readings, close limit switch(es) to alarm/shutdown;

adjust limit contact to correct limit point.

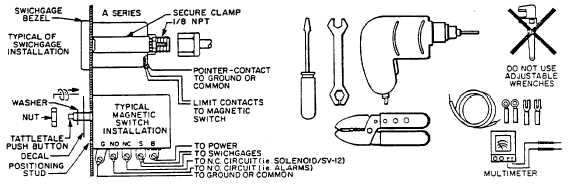

USE THE PROPER TOOLS - DO NOT OVERTIGHTEN

Murphy recommends mounting SWICHGAGE, and magnetic

switches away from excessive vibrations and the use of panel

shock mounts wherever vibration may occur. Handle all

instruments with care: although durable, these products should

not be subjected to rough handling, dropping, or severe

vibrations.

Magnetic Switches: Mount with electrical lugs down. If

necessary, drill the TATTLETALEâ and pilot-stud holes

(template provided); clean away burrs and filings. Position the

magnetic switch in the panel, making sure the pilot stud is in

place. Add TATTLETALEâ decal, then washer, then nut and

tighten.

BASIC WIRING OF SWICHGAGEâ AND MAGNETIC

SWITCH

Disconnect battery or other power during installation.

Murphy components are easily wired-up and maintained.

Use good quality wire and terminals. Be sure all connections

are Clean, Complete and Correct. The wiring and the type of

magnetic switch differ for various applications, but a knowledge

of basic electrical functions and of the circuits necessary for

the specific job (what you want to happen), and common sense

will make the system work the way you want It to work

See examples of typical wiring and instructions packed with

each magnetic switch.

IMPORTANT, PLEASE READ COMPLETELY

SWICHGAGE, Murphy magnetic switches and valves,

properly installed and maintained, are effective, work-ready

tools in any preventive maintenance program. For optimum

performance, check these tools periodically: look for frozen

pointers, kinked or worn tubing, broken wiring or loose

connections: close the contacts, then watch for expected

results. Replace any damaged or worn parts: clean and repair

as necessary. Murphy will repair or replace parts covered by

the Murphy two year limited warranty.

Check the wiring; it must be Correct and Complete: tight

connections, unbroken insulation, no accidental grounds,

do not run shut-down wires with ignition wiring.

Check all tubing and connections for leaks.

Mount magnetic switches and Murphy valves in an upright

position, to prevent moisture collection and shorting.

Cleaning Lexan Lenses: since many strong solvents and

cleaners can haze and permanently damage the clear poly-

carbonate lens on SWICHGAGE, please use one of the

solutions listed here: mild soap and water; mineral spirits;

white kerosene; VM&P naphtha; heptane; hexane; varsol No.

2; menthyl/isopropyl/isobutyl alcohols: 1 & 3 denatured

alcohols; freons TF & TE; petroleum ether (65C boiling pt.).

CAUTION: Many of these cleaners are

flammable. DO NOT USE when the

equipment is running or very hot. Keep

away from sparks and flame.