SERVICE MANUAL

MIDLAND-ROSS TRACTOR PROTECTION

VALVE

DESCRIPTION

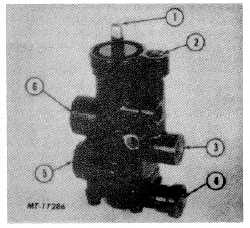

The tractor protection valve (Fig. 1) is normally

mounted at the rear of cab where tractor air system is

connected to the service and emergency air hoses used

for coupling tractor and trailer brake systems. Valve has

a piston arrangement that is pressure sensitive to tractor

air brake system, which provides automatic closing of

both lines when system pressure approaches low energy

levels. Manual actuation of the valve is performed by the

operator through use of a two-way air control valve.

When the control valve is opened (knob pushed in), air

pressure is supplied to control port to open the tractor

protection valve. Pulling air control "out" exhausts the air,

allowing the tractor protection valve to close.

Fig. 1 Tractor Protection Valve

1 Exhaust Port

4 Tractor Service

2 Control Port

5 Trailer Service

3 Tractor Emergency

6 Trailer Emergency

A quick release feature is also incorporated in the

valve and serves to improve normal service brake

release time of trailer brakes. During brake release,

control air delivered to actuate trailer brakes will exhaust

at tractor protection valve as compared to exhausting

through foot or hand control valves.

If either an automatic or manual operation closes the

tractor protection valve, air in the trailer emergency line is

exhausted through the tractor protection valve.

During normal tractor operation without trailer, the air

control valve is "out" and tractor protection valve is

closed. Air passages leading from tractor system to

trailer couplings are blocked.

After coupling a trailer to the tractor, the two-way air

control is pushed "in." Air flows through tractor protection

valve emergency line to charge trailer brake system

reservoirs. Trailer brakes are released simultaneously if

trailer brakes are holding prior to coupling.

During normal tractor-trailer operation, the tractor

protection valve remains open. It allows air to flow in

either direction between trailer air brake system and

tractor air brake system.

Trailer service brakes are applied and released by

driver’s operation of either the foot brake control or hand

control valve. Service brake control air flows through the

service passage of the tractor protection valve. Trailer

air reservoirs and brake system are replenished by air

flow through the emergency passage.

Driver can make an emergency trailer brake

application by moving air control valve "out." Tractor-to-

trailer service and emergency passages close and

exhaust passages open. Trailer brakes apply when air

exhausts from the trailer emergency line through tractor

protection valve exhaust passage.

The air control valve is moved "out" to close tractor

protection valve prior to disconnecting trailer from tractor.

OPERATION

Fig. 2 illustrates the tractor protection valve in the

closed position for operating a tractor without a trailer

(bobtailed). Refer to Fig. 2 for numbers and letters in

parenthesis.

Closed Position (Air Control Valve "Out")

Rubber valve (13) is seated against spool (7) closing

off passage of air through valve from tractor service (F)

to trailer service port (E). Exhaust valve assembly (5) is

seated against valve body (20) closing off passage of air

through valve from tractor emergency (G) to trailer

emergency port (D). The control port kH) and cavity "A"

are vented to exhaust through the two-way air control

valve on instrument panel. Both trailer emergency and

service ports (D and E) are open to atmosphere through

exhaust passages "B and “C”

Open Position (Air Control Valve "In")

When trailer hoses are connected to trailer, air

pressure is supplied from tractor air system to control

port (H) and enters cavity WA. Air pressure above 345

kPa (50 psi) acts against piston (17) to move it towards

spring (19). Piston seats against valve face of assembly

(5). Further movement pushes exhaust valve assem-

CTS-4079 - CHAPTER XI - Page 3