INSTALLATION

INSTALLING DRIVESHAFT

Drive Shaft Assembly - Place in a pair of centers and

check the shaft for runout if not previously done during

assembly. The runout on the tube should not be more than

.38 mm (.015") indicator reading, and on the neck of the slip

stub shaft the runout should not be more than .12 mm (.005")

indicator reading. Mark the high and low points on the shaft

with chalk and straighten if necessary. Install with the slip joint

nearest the source of power. Tighten the flange bolts evenly

after the nuts and NEW lockwashers are in place.

CHECKING DRIVESHAFT ANGLES

The procedure to check driveshaft angles for proper

universal joint operating angles follows:

1.

Remember to check driveshaft angles both with

the tractor fifth wheel unloaded, and loaded with

a trailer.

2.

To determine driveshaft angles, a spirit level

protractor is required (Fig. 43). When angles

are read from the 0 deg. Mark (for example,

measuring inter-axle shaft angle - 5 deg.),

record and use the angle shown on the

protractor. When angles are read from either of

the 90 deg. Marks (vertically) for example,

measuring yoke angles, do not record the angle

shown on the protractor since the 90 deg.

marks must be understood to be the same as 0

deg. On the horizontal plane. Thus, if a vertical

reading is 85 deg., the angle being measured is

5 deg.

3.

All angles should be read within 1/4 deg. (15

minutes) and they should be measured with the

protractor held plumb on a clean, flat surface.

4.

Inflate all tires to the pressure at which they are

normally operated. Park the tractor on a

surface which is as nearly level as possible both

from front-to-rear and from side-to-side.

5.

The tractor must be in its normal operating

position. Do not attempt to level the truck by

jacking up the front or rear axles to obtain a

level condition.

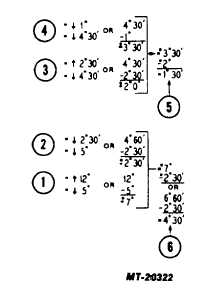

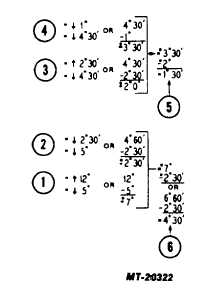

6.

Check and record the angle on the engine and

main transmission. This reading can be taken

at the rear of the main transmission on the

output yoke or flange. Record this reading on a

sketch similar to Fig. 44 (Example on Fig. 45, -

1 deg. down).

Fig. 43

7.

Move protractor to the 0 deg. reading and

check driveshaft angle between transmission

and forward axle (Example 4 deg. 30 sec.

down).

8.

Check front axle input yoke angle with protractor

(Example - angle up 2 deg. 30 sec.), also

check front axle output yoke (Example angle

down 2 deg. 20 sec.).

9.

Measure the angle of the tandem driveshaft

between the front axle and first rear axle

(Example 5 deg. down).

10.

Measure

the

rear

axle

input

yoke

angle

(Example 12 deg. up).

Fig. 44

See Page 23 for legend.

CTS-4017 - Page 22

PRINTED IN UNITED STATES OF AMERICA