S-SERIES INSTRUMENTS

AIR PRESSURE GAUGE

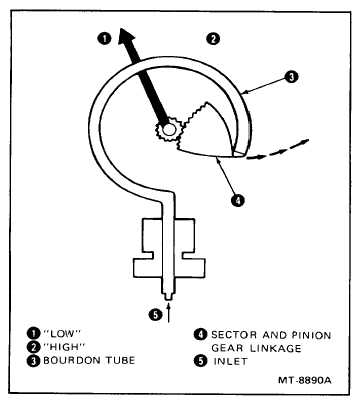

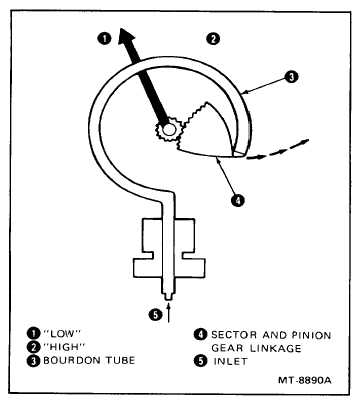

Operation

The air pressure gauges are the mechanical type and

operate on the Bourdon tube principle.

When air system is pressurized, air enters the air

pressure gauge and exerts pressure on the Bourdon

tube. As pressure increases, the Bourdon tube tends to

straighten out and thus actuate the sector and pinion

gear (Figure 22) to which it is attached. This causes

indicator to move across dial in an upscale direction.

When pressure decreases, the Bourdon tube relaxes

and pointer moves in a downscale direction. A steadily

applied air pressure holds the Bourdon tube and pointer

at a fixed scale reading corresponding to applied

pressure.

Figure 22 - Air Pressure Gauge Details

Removal

1.

Detach instrument cluster and cluster bezel.

2.

Unscrew air lines from fittings on rear of the two air

gauge inlets on back of instrument cluster.

3.

Remove gauge mounting screws and demount

gauges from instrument cluster (Figure 23).

4.

Separate

individual

gauges

from

bracket.

Figure 23 - Removing Air Pressure Gauges

Testing

1.

If a suspected gauge has been reading high and

does not return to zero when disconnected, Bourdon

tube has been damaged. Service by replacing with a

new gauge.

2.

If gauge has been reading low or does not read at

all, examine the inlet connection for dirt which might

restrict air from entering gauge. Make a trial

connection and if gauge still does not register

correctly, replace gauge.

NOTE - Always make a comparison test with a gauge

known to be reading correctly before discarding a

questionable gauge.

Installation

Installation of air gauges is the reverse of removal

procedure. Be sure to use non-hardening sealing com-

pound on fitting threads to prevent leaks. Check

installation so as to prevent kinks in air lines.

CTS-4140Y - Page 13