SERVICE MANUAL

GENERAL

Section 1

DISASSEMBLY

Special Tools

To overhaul the pump assembly, metric wrenches and

sockets will be required. Special rebuild tools called out

throughout the text will speed repair and protect parts

from damage. See Service Tool Chart (Section 1, Page

8).

PREPARATION

Pump and governor repair should be performed in a

clean area free from airborne dirt. A separate injection

room is preferred. Work bench, vise and tools should be

clean. The use of trays is recommended for keeping

injection pump parts in order. The pump assembly

should be thoroughly cleaned before disassembly. Use

only clean solvent and clean filtered test oil to clean

injection pump parts.

Prepare the pump for disassembly as follows:

1.

Drain fuel and lubricating oil from pump and

governor housings.

2.

Cap or plug fuel and lube oil openings after draining.

3.

Use clean diesel fuel or kerosene to clean exterior of

pump and governor assembly.

4.

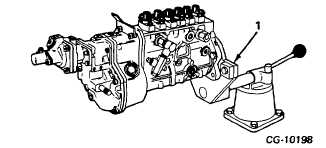

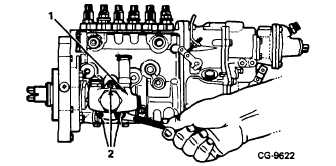

Clamp holding fixture KDEP 2919/A (Figure 1) in

vise. Remove two pump housing to adapter bolts.

Secure injection pump assembly to holding fixture.

Figure 1. Injection Pump Mounted in Holding Fixture

1.

Holding Fixture KDEP 2919/A

5.

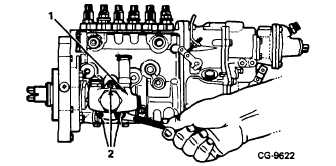

Remove fuel supply pump mounting bolts (Figure 2).

Remove supply pump and drain lubricating oil into a

container.

6.

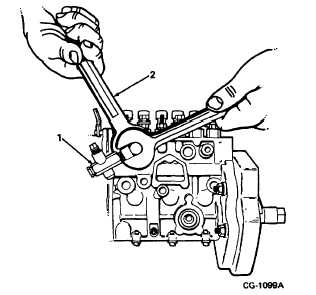

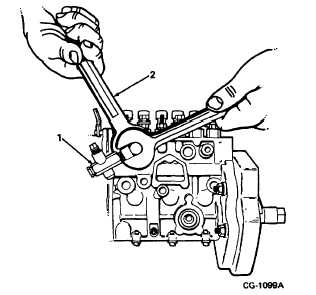

Remove fuel return valve. Hold adapter in place with

a 3/4 inch wrench while removing elbow and valve

body (Figure 3).

Figure 2. Removing Fuel Supply Pump

1.

Fuel Supply Pump

2.

Mounting Bolts

Figure 3. Fuel Return Valve Removal

1

Fuel Return Valve

2.

3/4 Inch Wrench

CGES-375

Printed in United States of America

Page 1