SERVICE MANUAL

Step 2 and recheck the radial shaft movement as

outlined in Step 3 (Fig. 10). If the readings exceed those

obtained in Step 3, indications are that the compressor

wheel is contacting the compressor housing and

servicing is required.

Fig. 10. Checking Radial Shaft Movement with

Compressor Housing Removed

COMPRESSOR END

Check

for

dirt

accumulation

inside

the

compressor housing.

COMPRESSOR WHEEL

Examine carefully for bent blades, evidence of

rubbing on O.D., face and back of wheel, and for pieces

of blade broken off. If any of these conditions exist,

wheel must be replaced.

TURBINE WHEEL

Remove core assembly from turbine housing.

Examine wheel carefully for evidence of rubbing on

housing. Check for bent or broken blades. Do not

attempt to straighten blades.

DISASSEMBLY

1.

Cover intake and exhaust ports. Wash the

exterior of the turbocharger.

Use a commercially approved cleaner

only. A caustic solution will damage certain

parts and should not be used.

2.

Place turbocharger on bench.

3.

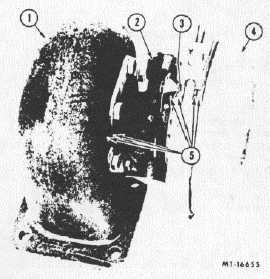

Mark the assembled position of parts (Fig. 11)

as follows:

a.

Compressor housing-to-back plate.

b.

Back plate-to-center housing.

c.

Center housing-to-turbine housing.

Fig. 11. Related Positions of Parts

1. Turbine Housing

2. Center Housing

3. Back Plate

4. Compressor Housing

5. Punch Marks

CTS-4104

PRINTED IN UNITED STATES OF AMERICA

Page 10