TM 5-3895-370-14&P

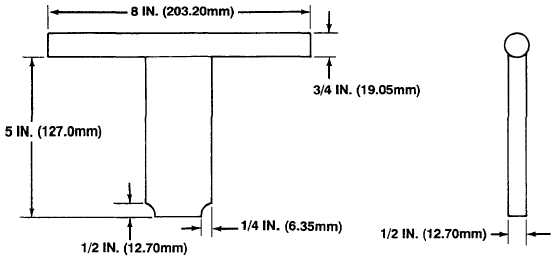

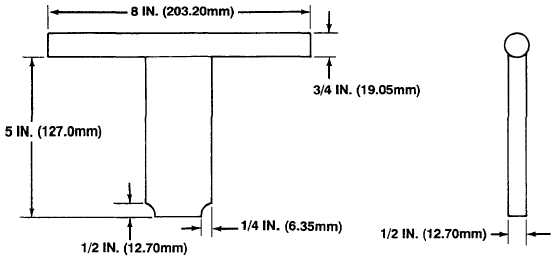

G-13. BEARING SLEEVE REMOVAL TOOL FABRICATION.

NOTES:

1.

FABRICATE ROD FROM 3/4 IN. (19.05 MM) COLD ROLLED STEEL.

2.

CUT ROD 8 IN. (203.20 MM) IN LENGTH.

3.

FABRICATE PLATE FROM 1/2 IN. (12.70 MM) THICK MILD STEEL STOCK

4.

CUT PLATE 2 IN. (50.80 MM) BY 5 IN. (127.00 MM).

5.

GRIND TWO ADJACENT CORNERS OF THE PLATE 1/4 IN. (6.35 MM) BY 1/2 IN. (12.70 MM) DEEP.

WARNING

UNSAFE WELDING PRACTICES CAN CAUSE SERIOUS INJURY FROM FIRE,

EXPLOSIONS, OR HARMFUL AGENTS. ALLOW ONLY AUTHORIZED PERSONNEL

TO WELD OR CUT METALS, AND FOLLOW SAFETY PRECAUTIONS IN TC 9-237.

PROTECTIVE

CLOTHING

AND

GOGGLES

MUST

BE

WORN;

ADEQUATE

PROTECTIVE EQUIPMENT USED, A SUITABLE FIRE EXTINGUISHER KEPT

NEARBY; AND REQUIREMENTS OF TC 9-237 STRICTLY FOLLOWED.

6.

WELD PLATE ON CENTER OF ROD WITH 5 IN. (127.00 MM) ON BOTH ENDS OF ROD.

7.

FILE OFF ROUGH EDGES.

Figure G-10. Bearing Sleeve Removal Tool

G-11/(G-12 blank)