TM 5-3895-370-14&P

Section V. GENERAL SUPPORT MAINTENANCE PROCEDURES

5-63. CYLINDER BLOCK REPAIR.

This task covers:

a. Inspection

c. Cleaning

b. Disassembly

d. Assembly

INITIAL SETUP

Tools

Materials/Parts - Continued

Shop equipment, automotive maintenance and

Oil, lubricating (item 34, Appendix E)

repair: field maintenance, supplemental

Compound, sealing(item 17, Appendix E)

no. 1, less power

Compound, sealing (item 18, Appendix E)

Shop equipment, automotive maintenance and

Equipment Condition

repair: field maintenance, supplemental

TM or Para

Condition Description

no. 2, less power

Para 5-12

Engine removed.

Para 4-31

Oil cooler removed.

Materials/Parts

Para 5-16

Cylinder head assembly

Chips, soap (item 10, Appendix E)

removed.

Detergent (item 19, Appendix E)

Para 5-68

Camshaft removed.

Solvent, drycleaning (item 50, Appendix E)

Para 5-65

Crankshaft removed.

a. Inspection.

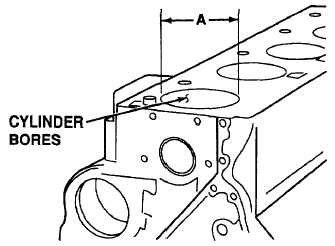

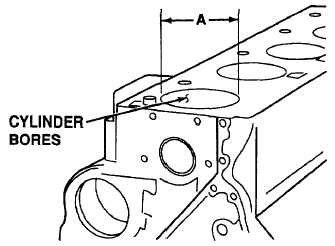

(1)

Check

cylinder

bores

at

position

A

approximately 1 in. (25.4 mm) deep and at 4.5

in. (114.3 mm) deep. Normal measurement is

4.0157 to 4.0203 in. (101.9988 102.1156 mm).

If

measurement

is

not

within

limits,

use

oversized pistons and rings to compensate.

5-253